Get Complete Project Material File(s) Now! »

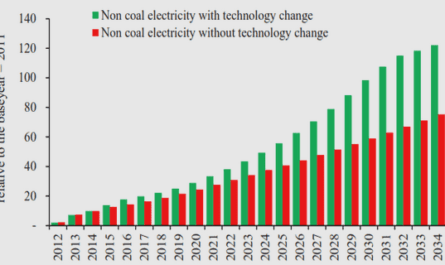

France, a Potential Vector of Growth for the European Anaerobic Digestion Sector

According to EurObserv’ER, (2014), along with UK, France is without any doubt the most promising country for AD development. The French Observation and Statistics Office reported an increase in the biogas production by 17% in 2013 and by 13% in 2012. For 10 years, regulation and public aids have been in favor of AD development in France. Ecology Minister, Ségolène Royal, reaffirmed her support for AD with the project to launch 1 500 biogas plants between 2014 and 2017. Public supports focus especially on biogas plants treating farm waste with the governmental project “Plan EMAA” (“Energie Méthanisation Autonomie Azote”) which aims to increase the number of agricultural biogas plants from 90 in 2012 to 1000 in 2020, with an average rate of 130 plants per year between 2013 and 2020. Biogas plants treating farm waste are strongly supported thanks to their ability to produce both biogas and fertilizers.

Digestate, the byproduct of biogas, is indeed supposed to replace conventional fertilizers and reduce the environmental impact of agriculture. France is the leader in Europe of the young organic waste AD sector. Since the deceleration of the market in their own country, German companies are eager to valorize their strong know-how on AD of energy crops and to install biogas plants in the emerging French market. Besides, new companies commercialize very new processes thought to be adapted to the sector. The actual statement reveals a lack of knowledge when dealing with the large diversity of substrates used in France. The technologies developed on energy crops indeed turns out to be unadapted to agricultural waste and appropriate solutions are slow in coming.

Although only a third of waste resources are today exploited, 40% of the biogas plants reported difficulties in substrates supply to feed the plants in 2015 (E-cube, 2015). These supply difficulties are mainly due to the lack of available resources inventory, many resources localization remaining unknown to the plant operators. Furthermore, the biogas plant operators are suspicious of accepting new substrate and changing the feeding strategy. Only few data about the resources are available and feeding poorly characterized substrates can lead to process inhibition or failure. The treatment of agricultural waste such as manure, slurry and straw with technologies adapted from energy crops remains a problem. 94% of the 56 installations surveyed by E-Cube (E-cube, 2015) reported operational incidents and 70% of the plants reported a profitability below their expectation. Moreover, 44% of the units reported a dysfunction of their AD plant and 31% a dysfunction in the co-generation unit. The main reason for dysfunction of the AD plant is a poor adaptation of the material to the substrates.

The diversity of substrates used induces quick changes in the operating conditions of the plant that can induce inhibitions or failures. The difficulties to anticipate the biological changes are attributed to a lack of formation for the operators as well as the instrumentation not adapted to the plant. A frequent solution found by constructors is the oversizing of biogas plants, which increases the cost of the installations. The hydraulic retention time ranges from a few hours up to 68 days in industrial effluent treatment plants, from 6 to 40 days on wastewater treatment plants and from 20 to 200 days on farm waste treatment plants (ATEE-Club biogas, 2011). This under-optimization of the plants affects the profits of this sector.

Due to reactor-oversizing and the difficulty to duplicate the plant designs, initial investment in biogas units in France remains high and depends on the digested substrate. The mean values are about 4,100 €/kWe (kiloWatt electric) for biogas plants treating industrial effluent, 6,300 €/kWe for biogas plants treating farm waste and 7,000 €/kWe for collective biogas plants treating mixed organic waste or wastewater treatment plants. Moreover, the cost of installation is not proportional to the capacity of biogas production: for biogas plants treating farm waste, investments vary from 15,000 €/kWe for a capacity of 35 kWe to 5,600 €/kWe for a capacity of 500 kWe (Bastide, 2015). The type of substrate treated and the electrical capacity of the plant are difficult to decouple, mean electrical power is 200 kWe, 441 kWe, 870 Kwe and 2,050 KWe for biogas plants treating agricultural waste (pulled up by collective biogas plants), industrial effluent, wastewater and household waste respectively.

The investment needed to produce 1 kWe for a 200 kWe biogas plant treating farm waste is around 50% more expensive than for a 440 Kwe biogas plant treating an industrial effluent. Operational expenditures (OPEX) vary with operational choices from 500 €/kWe to 1,500€/kWe and do not depend on the biogas production (E-cube, 2015). Since 75% of the biogas plant incomes are from electricity sales, biogas plants treating farm waste are penalized by the initial investment and compensate the loss of earning treating waste with treatment fees, FIT and premium for agricultural waste treatment which decrease with the increase of electrical power.

Government subsidies bring a financial support to biogas plant installations, targeted on the FIT and premiums for good practice, as reported in Table 1. Premiums are added to the FIT. In the case of “mixed” feedstock and biogas injection, the premium is weighted and calculated in proportion to the feedstock quantities used by the plant.

Batch Experiments to Determine Methane Yield and Methane Production Kinetics

MPR was estimated from the biological degradation of the substrate. Experiments were carried out in 8.5 L batch reactors with 6 L of sludge under mesophilic conditions as described in García-Gen et al., (2015). The substrates were grinded to approximately 1 cm. The reactor was fed at 1 gVS.L-1 in eight successive batches with the same substrate to adapt the micro-organism to the substrate. The biogas produced passed through a moisture trap and through a milligas counter fitted with a digital output (MGC-1 gas flow meters, DR.-ING.RITTER APPARTEBAU GMBH & CO, Bochum, Germany); the data were recorded online. Biogas composition was determined using a gas chromatograph (Perkin Elmer GC Clarus 480) equipped with two columns: the first one (RtUBond) was used at 110°C to separate CO2 and H2S from other gases, the second (RtMolsieve) was used at 70°C to separate O2, N2 and CH4. The injector and detector temperature was 200°C. The detection of gaseous compounds was done using a thermal conductivity detector. The calibration was carried out with a standard gas composed of 0.1% H2S, 0.5% O2, 10% N2, 25% CO2 and 64.4% CH4 (special gas from Linde gas S.A.).

The methane production of the last batch was used to obtain the MPR of the substrate. Methane yield was estimated as the maximal methane produced from 1 gram of dry matter on the eighth batch. Methane production times were selected on the MPR as values corresponding to the times required to reach a certain ratio of the methane yield from 5 to 95% with a regular increment of 5%. 2.3.3.2 BMP Test 0.8 gVS of the substrate were digested in batch anaerobic flasks. The volume of each flask was 573 mL, with a working volume of 200 mL. The flask contained a macroelements solution (NH4Cl, 26.6 g.L- 1; KH2PO4, 10 g.L-1; MgCl2, 6 g.L-1; CaCl2, 3 g.L-1), an oligoelement solution (FeCl2, 2 g.L-1; CoCl2, 0.5 g.L- 1; MnCl2 , 0.1 g.L-1; NiCl2, 0.1 g.L-1; ZnCl2, 0.05 g.L-1; H3BO3, 0.05 g.L-1; Na2SeO3, 0.05 g.L-1; CuCl2, 0.04 g.L-1; Na2MoO4, 0.01 g.L-1), bicarbonate buffer (NaHCO3, 50 g.L-1), an anaerobic sludge at 5 gVS.L-1 and substrate at 5 gTS.L-1. Once the flasks were prepared, degasification with nitrogen was carried out to obtain anaerobic conditions and the bottles were closed with red butyl rubber septum-type stopper which were air tight.

Triplicate bottles were incubated at 35°C. Biogas volume was monitored by using a manometric device (LEO 2, KELLER). Biogas composition was determined using GC as for batch experiments (2.3.3.1). The endogenous biogas production was determined following the biogas production of the sludge in the same condition without addition of substrates. Then, endogenous biogas production was withdrawn from the biogas production of the BMP test.

Batch Experiments for Hydrolysis Modelling

Two additional batch experiments were carried out for hydrolysis modelling:

wheat straw: after each chemical sequential extraction step, the remaining pellet was used as substrate for a BMP digestion test in order to evaluate each fraction’s biodegradation.

Apple: after each chemical sequential extraction step, the remaining pellet was used as substrate for a BMP digestion test in order to evaluate each fraction’s biodegradation.

Samples Analyzed for Fast Spectroscopic Characterization

This study was conducted with 90 samples chosen to represent a wide range of potential substrates for AD. More precisely, the analyses were conducted on 15 FOG, 25 fruits, 41 vegetables, 27 farm waste such as straw, manure or grass, 25 types of cereal, 6 kinds of meat or fish extracts, 4 types of micro-algae. All the samples were freeze-dried and grinded to less than 1 mm in size before any analysis. These 90 samples were mixed together to artificially increase the dataset with 195 mixed organic waste and improve the robustness of the regression models. The characteristics of these mixed organic waste were set as the weighted average of the initial substrates.

The MPR of the mixed organic waste were created in silico using the modified ADM1 (2.7.1) with parameters of kinetics defined on the MPR of the initial substrates. This approach was validated by García-Gen et al., (2015a). It leads to a database of 338 samples for COD, carbohydrate and nitrogen contents. The analysis of the lipid content was only performed on 231 of these samples, as the required amount of organic matter for lipid analyses was sometimes too large for certain samples with limited availability. The analysis of the methane production time was performed on 275 of these samples.

The analysis of the methane production yield was performed on 232 of these samples as the endogenous respiration disturbed the methane yield assessment on substrates with a slow methane production.

Pearson’s Correlation and Cosine

Pearson’s correlations calculate the correlations between the variables two by two by dividing their covariance with the product of their standard deviation. It provides a coefficient which varies in a range from -1 to 1, indicating respectively an anti-correlation or a correlation. Permutation tests with 9999 permutations were performed on the Pearson Correlation Coefficient (PCC) indicating if the coefficients were significantly different (alpha=0.05) from 0. The correlations between the b coefficients chosen for each PLSr model were assessed using cosine, package lsa from R.3.2.2, which measures the cosine between two vectors. Cosine varies in a range from -1 to 1, indicating respectively a negative co-linearity or a positive co-linearity. A value of 0 indicates the orthogonality of the two vectors. Heat maps and correlation networks were drawn using the package corrplot from R.3.2.2 which takes in consideration either PCC and p-values. The non-significant correlations were represented as non-existing correlations.

Principal Component Analysis

Principal Component Analysis (PCA) reduces the dimensionality of the data while retaining as much variance as possible (Al-Kandari and Jolliffe, 2005). PCA projects the data into the space spanned by orthogonal axis named principal components, which are a linear combination of the original variables. In this study, the original variables are carbohydrate, protein and lipid contents, COD, methane yield, biodegradability and methane production time expressed in days needed to reach a percent of the methane yield from 5 to 95%. For the PCA analysis, data were centered and scaled. The number of principal components has been chosen to represent 90% of the total variance. PCA was used as an exploratory tool to identify the variables that explain most of the variance within the data set and to assess the existing correlations between variables. In order to verify the accuracy of the PCA, projections of the samples on the principal components were also observed.

Table of contents :

Chapter 1. Anaerobic Digestion in Europe and in France.

1.1 Chapter Guidelines

1.2 Technical and Graphical Abstracts

1.3 World Energy Challenge

1.4 Biogas over European Union

1.5 France, a Potential Vector of Growth for the European Anaerobic Digestion Sector

1.6 Contents of the Thesis

Chapter 2. Materials and Methods

2.1 Materials and Methods Guidelines

2.2 Titrimetric Methods to Determine Ammonia Nitrogen, Volatile Fatty Acids and Inorganic Carbon Concentrations

2.2.1 Experimental Titration Device

2.2.2 Titration Protocol

2.2.3 Analytical Methods for Reference Data

2.2.4 Titration Model

2.2.5 Signal Processing Coupling pH and Electrical Conductivity Measurements

2.3 Analytical Methods for Solid Waste Characterization

2.3.1 Biochemical Composition of Solid Waste

2.3.2 Bio-accessibility Assessment by Chemical Sequential Extraction

2.3.3 Anaerobic digestion experiments

2.4 Spectroscopic Analyses

2.4.1 Near Infrared

2.4.2 3D Fluorescence

2.5 Solid Waste Analyzed

2.5.1 Samples Analyzed for Fast Spectroscopic Characterization

2.5.2 Samples Analyzed for Correlation Analyses

2.6 Correlation Analysis and Regression Models

2.6.1 Pearson’s Correlation and Cosine

2.6.2 Principal Component Analysis

2.6.3 Partial Least Square Regression Model and Performance

2.7 Dynamic Anaerobic Digestion Models

2.7.1 Dynamic Models: Modified ADM1

2.7.2 ADM1 Modelling Approach Using NIRs

Chapter 3. Combining pH and Electrical Conductivity Measurements to Improve Titrimetric Methods to Determine Ammonia Nitrogen, Volatile Fatty Acids and Inorganic Carbon Concentrations

3.1 Chapter Guidelines

3.2 Technical and Graphical Abstracts

3.3 Introduction of the Chapter

3.3.1 Key Parameters to Estimate the Biological State of Anaerobic Digestion Processes

3.3.2 Available Sensors for VFA, IC and TAN Concentrations Measurement

3.4 Materials and Methods Related to this Chapter

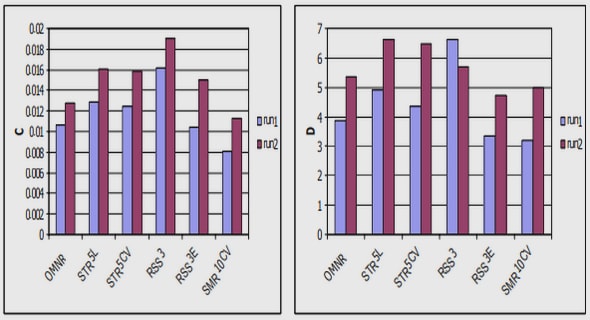

3.5 Results of the Existing Methods

3.5.1 Estimation of VFA and IC

3.5.2 Estimation of TAN Using Non-Linear Resolution

3.6 Accurate Estimation of VFA, IC and TAN Concentrations by Coupling pH and Electrical Conductivity Measurement.

3.6.1 Building of a Decision Tree

3.6.2 Example of a Titration Using SNAC

3.6.3 Discussion of the Advantages between the Existing Methods and SNAC

3.7 SNAC Prototype

3.8 Conclusion

Chapter 4. Relations between Biochemical Composition and Anaerobic Digestion Performances of Solid Waste

4.1 Chapter Guidelines

4.2 Technical and Graphical Abstracts

4.3 Introduction of the Chapter

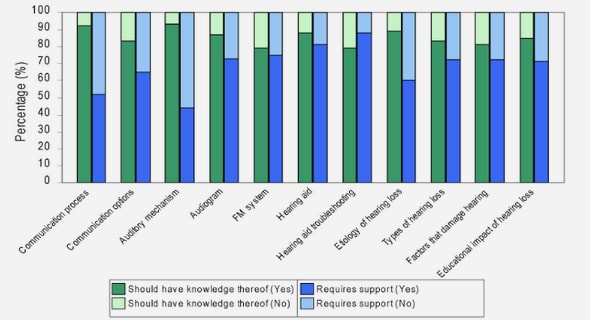

4.3.1 Analytical Methods for Biochemical Characterization of Substrates

4.3.2 Biodegradability and Methane Production Rate Estimation

4.4 Materials and Methods Related to this Chapter

4.5 Validation of Biochemical Analyses on Solid Waste

4.6 Dataset Exploration Using a Principal Component Analysis

4.7 Variables Correlation Exploration Using a Principal Component Analysis

4.8 Variables Correlation Analysis using Pearson Correlation Coefficients

4.9 Discussion about Variables Correlation Analysis

4.10 Predictability of the Kinetics of Methane Production from Biochemical Composition

4.11 Conclusion on the Existing Relation between the Biochemical Composition and the Methane Production Performances

Chapter 5. Characterization of the Solid Waste Biochemical Composition and Anaerobic Digestion Performances Using Spectroscopic Analyses

5.1 Chapter Guidelines

5.2 Technical and Graphical Abstracts

5.3 Introduction of the Chapter

5.3.1 BMP Estimation on Early Biogas Production

5.3.2 Spectroscopic Analyses

5.4 Materials and Methods Related to this Chapter

5.5 Comparison of 3D Fluorescence and Near Infrared Spectroscopy for Biodegradability Prediction

5.6 Fast Characterization of Solid Waste Biochemical Composition with Near Infrared Spectroscopy

5.6.1 Combinations of the Calibration Model Using PLS Regression

5.6.2 Model Validation on an Independent Dataset

5.6.3 Discussion Regarding the Selected Model

5.7 Prediction of the Methane Production Rate in Batch Conditions Using NIR Spectroscopy

5.7.1 Prediction of the Methane Yield

5.7.2 Prediction of the Methane Production Time

5.7.3 Methane Production Rate Prediction

5.7.4 Simple Indicator of Methane Production Performances

5.8 Confidence Interval Determination Using Spectrum Distance from the Calibration Set

5.9 Conclusion on NIRs Characterization

Chapter 6. Parallel Study of PLS b Coefficients and Near Infrared Wavelengths to Assess Molecules Contribution to Chemical Oxygen Demand, Methane Production Yield and Kinetics.

6.1 Chapter Guidelines

6.2 Technical and Graphical Abstracts

6.3 Introduction of the Chapter

6.4 Materials and Methods Related to this Chapter

6.5 Homogenization of the Chemometric Treatment

6.6 b Coefficients Analysis and Molecules Contribution to the Predicted Parameters

6.7 Relations between the b Coefficients of the Models

6.8 Conclusion

Chapter 7. Challenging the Simultaneous Hydrolysis Concept andFast Implementation of ADM1 for the Anaerobic Co-digestion Performances Simulation

7.1 Chapter Guidelines

7.2 Technical and Graphical Abstracts

7.3 Introduction of the Chapter

7.4 Materials and Methods Related to this Chapter

7.5 Modelling Hydrolysis: Simultaneous versus Sequential Biodegradation of theHydrolysable Fractions

7.5.1 Definition of Simultaneous and Sequential Concepts

7.5.2 Results Obtained on Several Substrates

7.5.3 Fractions Biodegradability: Case Studies on Apple and Wheat Straw

7.5.4 Case of Continuous Reactor

7.5.5 Conclusion on Hydrolysis Modelling

7.6 ADM1 Implementation Assisted by Near Infrared Spectroscopy for the Anaerobic Digestion Performances Simulation

7.6.1 ADM1 Calibration from NIR Prediction

7.6.2 Discussion on the MPR Prediction Using NIR

7.7 Example of Industrial Application

7.8 Conclusion

Chapter 8. General Conclusion and Outlooks

8.1 Conclusion

8.2 Outlooks

8.3 Projected development

Chapter 9. References