Get Complete Project Material File(s) Now! »

Magnetic sensors for biomedical applications

Biomagnetic signals are characterized by low magnitude and low frequency (DC – few kHz) signals. In general, the choice of the sensor is driven by the nature of the sources and the signal of interest.

Proper sensors for biomagnetic signals are chosen according to the following parameters:

• Source characteristics (point-like or distributed, dipolar, quadrupolar…).

• Distance between the source and the sensor (which leads to the amplitude of the signal at the sensor location).

• Allowable size.

• Environmental conditions (in air for a non-invasive recording or in the conductive medium of the tissues for invasive recordings).

Biomagnetic signals when recorded non invasively, like in MEG or MCG, are distant to the source, exhibit low amplitude and can allow centimeter size sensor.

On contrary, local biomagnetic recordings, as those targeted in this work, are defined by a closer distance to the signal source, and therefore larger amplitudes signals, even though not expected to be larger than few nT; they required miniaturized sensors to fit to the small structures studied and limits the damages due to the penetration in the tissues. The sensor should also operates at physiological temperature and be compatible to the tissues environment, i.e. does not contaminate the living tissues with toxic materials, neither be corroded by the ions and natural chemicals of the tissues.

For non-invasive recordings, ultra-sensitive magnetometers should be used to allow record- ings with a reasonable number of averages. The two main types of magnetic sensors are field sensors and flux sensors. Flux sensors sensitivity is proportional to the effective surface over which the field is applied (on SQUIDS, usually a pickup coil that contains several turns is used; the effective surface is the mean surface area times the number of turns, and the flux to consider is also depending on the inductance of the pickup coil), and though large surface sensors can offer a very high sensitivity. SQUIDs and atomic magnetometers are the main sensors used for MCG and MEG recordings.

Spin Valve -Giant MagnetoResistance

If GMR has been first demonstrated in multilayer structures, alternating magnetic and non magnetic very thin (nm range) layer, this type of structure is not ideal for a sensor application since the MR varies over a large field range, and thus does not exhibit the highest sensitivity. We will therefore focus here and the specific GMR structure chosen for magnetic field sensor application, discovered by Dieny in 1991 [59], the Spin Valve (SV) structure.

Random Telegraphic Noise (RTN)

Random Telegraphic Noise corresponds to fluctuations between two or several discrete levels with comparable energies to the presence of defects in the conductor. This is usually the main source of noise in semi-conductors. In MR sensors, these fluctuations originate mainly from the soft layer, where domain walls can be formed and thus several energetic configurations appear, inducing resistance fluctuations between the states.

In small size GMR sensors, defects become dominant and RTN noise can appear: (cf chapter 3, sharp magnetrode). These jumps are strongly dependent of the temperature, field and the applied bias current.

Probes microfabrication

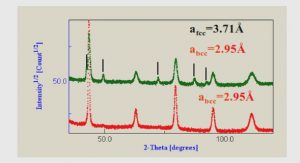

Spin valve stacks Two SV types of stacks have been used for magnetrode processing: the first one (figure 3.4), deposited by INESC-MN is a simple SV, deposited on 150-200 μm silicon substrates. These stacks were used for the first sets of sharp magnetrodes, but their final sensitivity was shown to be too low to be used in the in vivo and in vitro recordings. The second type of stacks is a Synthetic Anti-ferromagnet based GMR, deposited on standard 700 μm thick silicon substrate by AllegroMicrosystems. It has been used for the planar probe, and the substrate has been grinded down to 200 μm after stack deposition for the sharp probes.

Photolithography Photolithography is used to reproduce geometric patterns on a sample by using UV light passing through a mask. Patterns are defined on an optical mask made in quartz allowing UV light to shine through and opaque area made in chromium stopping UV light. All optical masks were designed with a homemade software and fabricated by an external company (Toppan). The sample is carefully cleaned with solvents then spin coated with a light-sensitive polymer resist (or photoresist) before being exposed to light. If the photoresist is positive, a developer removes the exposed area while areas hidden by chrome reveals desired patterns. All lithography processes developed for magnetrodes were done in the clean room of SPEC/Saclay and follow the steps below:

1. Sample preparation: in order to remove any particules contamination and obtain a good resist adhesion as well as an uniform coating, the sample was cleaned in acetone and isopropanol in an ultrasound bath heated at 70°C. Ultrasounds were not used for substrates thinner than 200 μm to avoid breaking it. All samples are then rinsed with deionized water to remove any alcohol traces.

2. Spin coating: after a proper drying, the sample is coated with a positive photoresist chosen according to its thickness properties. The first lithography in sharp probe process is dedicated to reproduce GMR sensor pattern on the thin substrate. Since the total SV stack thickness is lower than 50 nm, we used S1813 photoresist which deposits a thin film of 1.3 μm resist for coating speed of 5000 rpm. The sample is held by vacuum on a spinner chuck and photoresist is deposited on the surface to uniform thickness by spin coating. Both viscosity of the photoresist and spinner rotational speed define the resist thickness by the help of a high speed centrifugal system.

3. Soft baking: Once resist is spin coated, the sample is softly baked at 110° C for 3 minutes on a hot plate to evaporate the coating solvent and densify the resist.

Measurement methods and probe characterization

Neuromagnetic field detection involves very weak signals measurement and localization, thus is it essential to previously characterize the sensors to precisely know their performances. Sensor characterization gives sensor behavior under a known and calibrated magnetic field. To fully characterize the sensor, two types of transport measurements were performed on the sensors; magneto-transport, which gives the sensitivity, the magnetoresistance ratio and the linearity of the sensor, and noise measurements, which lead to the field equivalent noise in the frequency range of interest (here between 1 Hz and few kHz typically). The methods used and the obtained performances on the probes are shown in this part. Finally, in order to mimick neurons behavior, we developed a phantom which consists of reproducing small neuromagnetic field distribution in a conductive solution close to the one present within biological tissues. Phantom experiments were also performed to test sensors biocompatibility.

Nerve-muscle junction physiology

The neuro-muscular system is the junction between a motor neuron and a skeletal muscle; it is a well-studied and understood system for synaptic transmission mostly thanks to the basic features of chemical synaptic transmission, which involves a relatively simple mech- anism: in contrast to central nerve cells which have convergent connections, muscle cells are mono-innervated with a single excitatory synapse (Figure 4.1). The nerve contains a hundred of axons and is connected to the muscle fibers by synapses that release neurotrans- mitters acetylcholine (ACh) to open voltage-gated Na+, K+, Mg2+ and Ca2+ channels located at the post-synaptic cell (i.e the muscle fibers). Contrary to cardiac and smooth muscles, skeletal muscle can be movement-controlled by nervous stimulation to trigger Action Poten- tials (APs), eliciting a post-synaptic potential at the level of the nerve muscle synapse that conducts to the propagation of an AP along the muscle followed by a contraction [3].

Table of contents :

1 Neurophysiology

1.1 Biology of neurons

1.1.1 Structure of neurons

1.1.1.1 From brain to neuronal cells

1.1.1.2 Neuron morphology

1.1.2 Function of neurons

1.1.2.1 Ions flux across the neural cell membrane

1.1.2.2 Neurotransmission

1.1.2.3 Action Potential

1.1.2.4 Local Field Potential

1.2 Electrophysiology

1.2.1 Macroscopic scale

1.2.1.1 Electroencephalogram – EEG

1.2.1.2 Electrocorticography – ECoG

1.2.2 Mesoscopic scale

1.2.2.1 Extracellular recordings

1.2.2.2 Optical techniques

1.2.3 Microscopic scale

1.2.3.1 Intracellular recordings

1.3 Magnetophysiology

1.3.1 Brain scale: magnetoencephalography

1.3.2 Local measurements

1.3.3 Magnetic field created by neurons

1.3.3.1 A very simple model of a single neuron

1.3.3.2 More sophisticated models of a single neuron

1.3.3.3 Assembly of neurons

1.3.3.4 Analysis of the models

1.3.4 Conclusion

2 Magnetic sensors

2.1 Magnetic sensors for biomedical applications

2.1.1 Magnetic field amplitudes

2.1.2 Magnetic sensors for biomedical applications

2.1.2.1 SQUIDs

2.1.2.2 Atomic magnetometer

2.2 Magnetoresistive sensors

2.2.1 Spin electronics

2.2.2 Spin Valve -Giant MagnetoResistance

2.2.2.1 Sensor Magneto-Resistance (MR) ratio and sensitivity

2.2.3 SV sensor

2.2.3.1 Sensor shape

2.2.3.2 Contacts

2.3 Noise sources

2.3.1 Detectivity

2.3.2 Thermal noise (Johnson noise)

2.3.3 1/f noise (Flicker noise)

2.3.4 Random Telegraphic Noise (RTN)

2.3.5 Magnetic noise

2.4 Conclusion

3 Magnetrodes

3.1 Probes fabrication

3.1.1 Sharp probe

3.1.1.1 Probe design

3.1.1.2 Sensor design

3.1.1.3 Probes microfabrication

3.1.1.4 Dry etching

3.1.1.5 Deposition techniques

3.1.1.6 Final probe shape

3.1.2 Planar probes

3.1.2.1 Probe design

3.1.2.2 Planar probe fabrication

3.1.3 Probes packaging

3.1.3.1 Connection

3.1.3.2 Packaging

3.2 Measurement methods and probe characterization

3.2.1 Magneto transport characterization methods

3.2.1.1 R(H) transfer curve

3.2.1.2 Response

3.2.1.3 Noise

3.2.2 Measurement methods

3.2.2.1 DC measurement

3.2.2.2 Capacitive coupling

3.2.2.3 AC measurement (frequency demodulation)

3.2.2.4 Sensitivity measurements

3.2.3 Probes characterization

3.2.3.1 Planar probes

3.2.3.2 Sharp probes

3.3 Phantom

3.3.1 Setup

3.3.2 Results

3.4 Conclusions

4 In vitro recordings

4.1 Muscle experiment

4.1.1 Context and Objectives

4.1.1.1 Nerve-muscle junction physiology

4.1.1.2 Magnetic response modeling

4.1.1.3 Objectives

4.1.2 Experiment / Methods

4.1.3 Magnetic recordings

4.1.3.1 Magnetic sensors

4.1.3.2 Magnetic signal recordings

4.1.3.3 Geometry study

4.1.3.4 Pharmacology

4.1.3.5 Tetanus

4.1.3.6 Artefacts

4.1.3.7 Signal-to-noise

4.1.4 Electrophysiology recordings

4.1.5 Modeling

4.1.6 Discussion

4.2 Hippocampal slices experiment

4.2.1 Context and Objectives

4.2.1.1 Hippocampus physiology

4.2.1.2 Objectives

4.2.1.3 Simulation

4.2.1.4 Slice experiments

4.2.1.5 Magnetic recordings with sharp probes

4.2.1.6 Conclusion

5 In vivo recordings

5.1 Objectives

5.2 Experiments / Methods

5.2.1 Sensors

5.2.1.1 Planar sensor

5.2.1.2 Sharp sensors

5.2.2 Experimental protocol

5.3 Results

5.3.1 AC mode

5.3.2 DC mode

5.3.3 Control experiments

5.3.3.1 I=0

5.3.3.2 Tangential direction

5.3.3.3 Removing tungsten

5.3.4 Conclusion and perspectives

Bibliography