Get Complete Project Material File(s) Now! »

SEM and SEM-EBSD

The microstructure, composition and microscopic crystallographic features of NiMnGa thin films were investigated by the field emission gun scanning electron microscope (FEG-SEM, JEOL-6500F). The composition of the NiMnGa films were investigated by the energy dispersive X-ray spectrometry system (EDS, Bruker) attached this SEM. The morphology and microstructure of the NiMnGa thin films were characterized by the secondary electron image and backscattered electron image. The microstructure and the microscopic crystallographic orientations of the NiMnGa martensite variants were analyzed using the same SEM equipped with an EBSD acquisition camera (Oxford HKL) and acquisition software (Oxford Channel 5). The EBSD patterns from the martensite variants were manually acquired using Channel 5 Flamenco’s interactive option.

The sample for SEM-EBSD analysis was electrolytically polished with the solution of 20%HNO3 in volume in CH3OH at room temperature.

TEM

Philips CM 200 TEM with 200 kV accelerating voltage and LaB6 filaments has been used to observe fine martensite variants in NiMnGa thin films. JEOL-2100F HR-TEM with field-emission gun was used to investigate the atomic-level stacking faults between variants within martensite plates.

Specimens for TEM investigation were cut off out the freestanding NiMnGa thin film and further thinned using twin-jet electrolytic polishing with an electrolyte of 20% HNO3 in volume in CH3OH at ambient temperature.

Crystallographic calculations

With the precise crystallographic orientations of martensite variants, the orientation relationships between the martensite variants and their interfaces, and orientation relationship between austenite and martensite can be calculated. In addition, the following presents the calculation methods used in the present work.

Stereographic projection and traces determination (2-23)

The stereographic projection is a particular mapping that projects a sphere onto a plane, which is one of the projection methods to calculate pole figures. To calculate the pole figure of crystal directions or plane normal vectors, the vectors have to be expressed in the macroscopic coordinate system set with respect to the equatorial plane (for example the sample coordinate system) t before the stereographic projection. For instance, when a plane normal vector is VPhkl* . The corresponding vector in the sample coordinate system VS can be calculated using Eq. (2-24). VS MEMCSiG*VP (2-24).

Here, ME is the Euler angle matrix, MC is the coordinate transformation matrix from the orthonormal crystal coordinate system to the Bravais lattice basis. Si is the symmetric element of a crystal, G * is the metric tensor in reciprocal space. Then, the vector VS T should be normalized to unit vector. [t1,t2 ,t3 ].

Influence of substrate temperature and seed layer on the epitaxial thin films

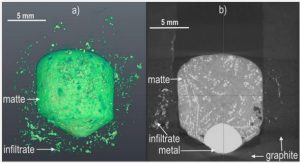

Fig. 3.5 SEM-image of NiMnGa thin films deposited on MgO(100) at two substrate temperatures (a-c)400℃, (d-f) 500 ℃.

The above results show that the NiMnGa thin films deposited on silicon substrate is of column structure due to the polycrystallization of the high temperature austenite. Although the post annealing is helpful to increase the column thickness size and promotes martensitic transformation it cannot change the mono-crystallinity of austenite. Therefore, monocrystalline MgO(100) substrates were used to fabricate the epitaxial NiMnGa thin films. During the deposition, certain Mn and Ga are lost resulting in high Ni concentration, the target composition with reduced Ni concentrations were used, as shown in Table 3.3.

Fig. 3.6 NiMnGa thin films deposited on MgO(100) at different substrate temperature(a)400℃, (b) 500 ℃. Fig.3.6 shows the X-ray diffraction patterns of the NiMnGa thin film deposited on the MgO substrate. X-ray diffraction spectra show that the crystal structure of these thin films is of those of 7M martensite and austenite.

Determination of crystallographic texture

Fig.4.3 presents the pole figures of NM martensite and 7M martensite. Let the edges of MgO substrate as the macroscopic sample coordinate system as shown in Fig.4.3(a) and the crystal direction of [100]MgO parallel to the starting position of the azimuth angle. It should be noted that the pole figures are incomplete pole figures. Only the central part of these pole figures was shown, since the martensites of NiMnGa possess strong in-plane texture and the information in the central part is enough to represent the texture characteristics of the film.

It is seen that from Fig.4.3 the NM martensite is with its (004)Tetr or (220)Tetr close to the substrate surface, demonstrating a typical plane texture, while 7M martensite is with its (2 0 20)mono, (2 0 20 )mono or (0 4 0)mono close to the substrate surface, also demonstrating a plane texture. It should be mentioned that for the (2 0 20)mono pole figure, the central pole is originated from the (2 0 20)mono plane of 7M martensite and (004)A plane of austenite. The four poles with 6°tilt angle are from the diffraction of (2 0 23)mono plane. Due to the structure modulation of 7M martensite, the two planes possess very close interplanar spacing.

As shown in Fig.4.3, the high intensity pole areas are clearly separated and distributed symmetrically with respect to the film surface normal. This indicates that the film possesses several strong preferred orientations that may be related to the specific orientation of different martensite variants. As XRD measurements capture only global orientation information from the film and the pole figures represent this global information with respect to the macroscopic sample coordinate system, it is difficult to correlate the poles with individual martensite variants in the microstructure. To further resolve such information, Local SEM-EBSD orientation determination is needed.

Table of contents :

Chapter 1 Introduction

1.1 General introduction

1.2 Ferromagnetic shape memory effect

1.3 Bulk NiMnGa Heusler alloys

1.3.1 Phase constituents and their crystal structures of NiMnGa alloys

1.3.2 Twin boundaries of martensites in NiMnGa alloys

1.3.3 Orientation relationship between martensite variants in NiMnGa alloys

1.3.4 Orientation relationship governing martensitic transformation

1.4 NiMnGa thin films

1.4.1 Fabrication process

1.4.2 Phase constituent, microstructural and crystallographic features

1.5 Content of the present work

Chapter 2 Experimental and crystallographic calculation

2.1 Sample preparation

2.1.1 Preparation of sputtering target

2.1.2 Thin film deposition

2.2 Characterization

2.2.1 X-ray diffraction

2.2.2 SEM and SEM-EBSD

2.2.3 TEM

2.3 Crystallographic calculations

2.3.1 Fundaments and definitions

2.3.2 Determination of orientation relationships

2.3.3 Displacement gradient tensor

Chapter 3 Fabrication of NiMnGa thin films

3.1 Introduction

3.2 Experimental procedure

3.3 Results

3.3.1 Influence of sputtering parameters and post annealing

3.3.2 Influence of substrate temperature and seed layer on the epitaxial thin films

3.3.3 Influence of film composition and thickness

3.4 Discussion

3.5 Summary

Chapter 4 Determination of crystal structure and crystallographic features by XRD

4.1 Introduction

4.2 Experimental

4.3 Results and discussion

4.3.1 Determination of crystal structure

4.3.2 Determination of crystallographic texture

4.4 Summary

Chapter 5 Determination of crystallographic features of epitaxial NiMnGa thin films by EBSD

5.1 Introduction

5.2 Experimental procedure

5.3 Results

5.3.1 Microstructure of epitaxial NiMnGa thin films

5.3.2 Crystallographic features of NM martensite

5.3.3 Crystallographic features of 7M martensite

5.3.4 Crystallography and sequence of martensitic transformation

5.4 Summary

Chapter 6 Conclusions

6.1 Conclusions

Bibliography