(Downloads - 0)

For more info about our services contact : help@bestpfe.com

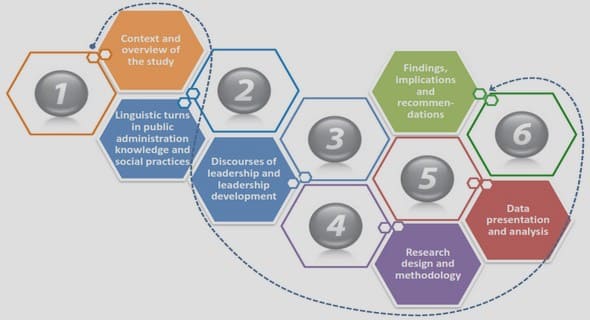

Table of contents

1. Introduction

1.1 Overview and History

1.2 Purpose

1.3 Research Questions

1.4 Delimitations

1.5 Method

1.5.1 Literature studies

1.5.2 Interviews

2. Theoretical Principles

2.1 Value Analysis (VA)

2.2 Quality Function Deployment (QFD)

2.2.1 Benchmarking

2.3 Failure Mode and Effects Analysis (FMEA)

2.4 Design for Assembly (DFA)

2.4.1 Design for Automatic Assembly (DFA2)

2.5 Modular Function Deployment (MFD)

2.6 Earlier Studies

3. Methods that are used in today’s industry

3.1 Atlas Copco Tools

3.1.1 Profitability calculations and the view of Value Analysis

3.1.2 Development with customer as focus

3.1.3 Error Analysis – Risk analysis a more appropriate method than FMEA

3.1.4 Assembly

3.1.5 Modular System – Future method of product development

3.1.6 Environment

3.2 Scania

3.2.1 Value Analysis – A question of fashion

3.2.2 Quality and Customer – Scania and Rivals

3.2.3 Error Analysis – Focus on FMEA

3.2.4 Assembly

3.2.5 Modular System – Veteran Scania

3.2.6 Environment

3.3 ABB – Force Measurement Department

3.3.1 Value Analysis – Cost vs. Performance

3.3.2 Customer and Quality – Basic functions and unique measurement principles

3.3.3 Error Analysis – Trial by customers

3.3.4 Assembly

3.3.5 Modular System – Software Modularization

3.3.6 Environment

4. Similarities and Differences between Practice and Theory

4.1 In Context of Value Analysis (VA)

4.2 In Context of Quality Function Deployment (QFD)

4.3 In Context of Failure Mode and Effects Analysis (FMEA)

4.4 In Context of Design for Assembly (DFA)

4.5 In Context of Modular Function Deployment (MFD)

5. Conclusion – How applicable are the theoretical methods in practice?

6. Discussion

6.1 How to improve the product development

6.2 What will the future look like?

7. Critical Assessment

8. References

8.1 Books

8.2 Articles

8.3 Reports

8.4 Persons

8.5 Websites