(Downloads - 0)

For more info about our services contact : help@bestpfe.com

Table of contents

1 Context and problemstatement

1.1 A brief history of the dry cleaning

1.2 The ARCACLEAN solvent

1.3 Motivations and problem statement

1.3.1 Current regeneration process in ARCAFLEX320 machines

1.3.2 Issues and limitations of distillation

1.3.3 Dry cleaning devices without distillers

1.3.3.1 « IPURA » by ILSA

1.3.3.2 « NEBULA » by Renzacci

1.3.3.3 UNISEC

1.3.4 Other classic dehydration processes

1.3.4.1 The extractive distillation

1.3.4.2 The adsorption

1.3.4.3 Membrane processes

1.4 Thesis workflow

2 Thermodynamics of solvents: theoretical and experimental study

2.1 Experimental measurements of solvents properties

2.1.1 Experimentalmaterials and methods

2.1.1.1 Materials

2.1.1.2 Working principle of a static apparatus

2.1.1.3 Treatment of experimental points

2.1.2 Sample analysis by the gas chromatography

2.1.2.1 Importance of the quantitative sample analysis

2.1.2.2 Analysis performing

2.1.2.3 Peaks identification and calibration

2.1.3 Experimentalmeasurements workflow

2.1.3.1 Pure compounds vapor pressure

2.1.3.2 VLE and VLLE of aqueous binary mixtures

2.1.3.3 VLE of organic binary mixtures

2.1.3.4 VLE of the quaternary mixture ARCACLEAN + water

2.2 Thermodynamic modelling of phase equilibria occurring inH2O+ARCACLEAN mixtures

2.2.1 Pure compounds parameters estimation

2.2.1.1 Definition of the equation of state parameters

2.2.1.2 Application of the Peng-Robinson EoS to glycol ethers

2.2.1.3 Fitting of estimated pure compound properties

2.2.2 Prediction of low-pressure phase equilibria using the NRTL-PRmodel

2.2.2.1 Generalized NRTL model

2.2.2.2 Generalized reference state at constant volume GRS-CV

2.2.2.3 Association of the generalizedNRTL modelwith the Peng-Robinson EoS

2.3 Results and discussion

2.3.1 VLE of all binary mixtures

2.3.2 VLE of the quaternary mixtures

2.4 Chapter conclusion

3 Pervaporation as an alternative process for solvent dehydration in dry cleaningmachines

3.1 Literature review

3.1.1 Pervaporation overview

3.1.2 Materials of pervaporation membranes

3.1.2.1 The organic membranes

3.1.2.2 The inorganicmembranes

3.1.2.3 The hybrid membranes

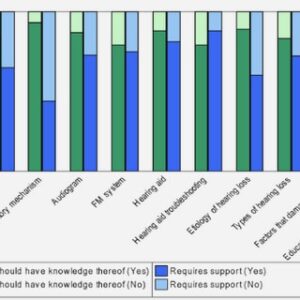

3.1.3 Dehydration of organic solvents by pervaporation

3.2 Experimental study of solvent dehydration by pervaporation

3.2.1 Materials

3.2.2 Experimental unit description

3.2.3 Analysis by gas chromatography

3.2.3.1 GC device

3.2.3.2 GC operating parameters and setup

3.2.3.3 GC Calibration

3.2.4 Results and discussion

3.2.4.1 Membrane Sultzer PERVAP 4102-3184

3.2.4.2 Membrane Sultzer PERVAP 4510-2898

3.2.4.3 Membrane Sultzer PERVAP 4100-3239

3.3 Modelling of solvent dehydration by the solution-diffusion model

3.3.1 General approach to mass transfer modelling in polymeric membranes

3.3.2 The solution-diffusion model

3.3.2.1 Brief mathematical description

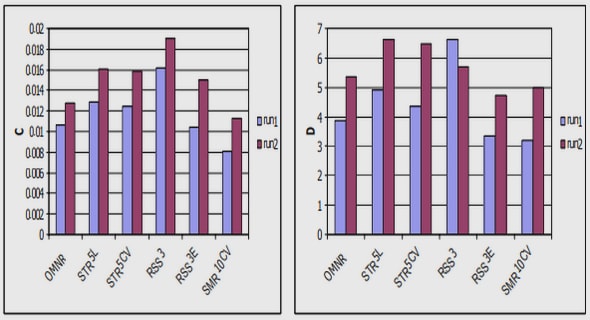

3.3.2.2 Reporting the pervaporation data

3.3.3 Determining the activity coefficients for solution-diffusion model

3.4 Results and discussion

3.4.1 Influence of temperature

3.4.2 Influence of feed concentration

3.4.3 Prediction of membrane performance in batch dehydration at different temperatures

3.5 Chapter conclusion

4 On the design of the pervaporation unit for solvent dehydration and its integration in the dry cleaning machine

4.1 ARCAFLEX320 distillation system

4.1.1 Overview and working principle

4.1.2 Devices that can be reused

4.1.3 Process constraints

4.2 Design of the pervaporation unit

4.2.1 Membranemodule

4.2.2 Vacuum system

4.2.3 Permeate condenser

4.2.4 System layout

4.2.5 Operational costs estimation and comparison with distillation

4.3 Chapter conclusion

Conclusions and directions for future research

Bibliography

Appendix A Literature reference states and expressions for g E

A.1 Zero pressure reference state (Michelsen, 1990)

A.2 Infinite pressure reference state (Huron and Vidal, 1979)

A.3 Constant packing fraction (Peneloux et al., 1989)

A.4 Generalized reference state at constant volume (Neau et al., 2011)

Appendix B Pure compounds group contribution parameters for the estimation of critical properties

AppendixC Measured experimental vapor pressures and VLE data for purecompounds, binary and quaternary mixtures

C.1 Pure compounds

C.2 Aqueous binary mixtures

C.3 Organic binary mixtures

C.4 Quaternarymixtures

Appendix D GC setup and operating conditions used in Chapter 2

Appendix E Membrane cell used in experiments for the laboratory scale pervaporation