Get Complete Project Material File(s) Now! »

Foam structure and structural changes due to destabilisation processes

Liquid foams are concentrated dispersions of gas bubbles into a liquid. The foam structure can be described at different length scales (Fig. II.1). First, an interface with adsorbed surfactant separates water from air. Second, neighbouring bubbles are separated by a liquid film, or lamella, with two gas-liquid interfaces. Third, three films junction form a canal called Plateau border (Cantat et al., 2013).

To define the foam structure, the bubble radius R, the liquid volume fraction φ and the interfacial tension σ are relevant parameters (Dollet and Raufaste, 2014). The bubble shape evolves with a decreasing liquid fraction φ, defined as the ratio of the liquid volume to the foam volume, from spherical bubbles (φ>0.36) to polyhedral bubbles with pentagonal faces (φ<0.05) (Drenckhan and Hutzler, 2015). Theoretical foam models generally involve dry foam with polyhedral bubbles.

Creating an interface between gas and liquid requires energy, called interfacial tension σ. Interfacial tension determines the shape of the interface by the Laplace equation: ΔP= σ/R (eq. 1) where ΔP is Laplace pressure (Pair – Pliquid). Interestingly, the interfacial tension acts to flatten the interface whereas the Laplace pressure curves it (Fig. II.2) (Cantat et al., 2013).

The structure of dry foams is also described by Plateau’s laws, due to the minimisation of total interfacial area. Three lamellae meet symmetrically under angles of 120° in channels, the so-called Plateau border junction (Fig. II.3) (Drenckhan and Hutzler, 2015). When the length of a Plateau border shrinks to zero because of local strain, an unstable configuration according to Plateau’s laws is obtained. Then, elementary topological changes called T1 occur, independently or as avalanches. A T1 corresponds to a bubbles neighbour switching. Another topological change exists called T2, which corresponds to the vanishing of a bubble, which is replaced by a node (Höhler and Cohen-Addad, 2005).

The mechanical behaviour of foams combined with their low density and their large interfacial area lead to a wide variety of industrial applications. From a rheological point of view, a foam behaves as a solid or a liquid depending on the applied strain Fig. II.4. When a small strain is applied to a foam sample, the bubbles are deformed and thus their interfacial area and interfacial energy increase, giving rise to an elastic stress. The elastic and loss moduli are constant (G’0 and G”0): this is the linear regime of the stress versus strain relationship. If the applied strain is increased beyond the yield strain (respectively, if the stress is increased above a yield stress), bubbles start to rearrange and the foam flows as a liquid. The yield strain (or stress) corresponds to the onset of plastic events, i.e. irreversible bubble rearrangements, called T1s, represented in Fig. II.3. Yield stress can be measured by oscillatory rheometry using an amplitude sweep (Saint-Jalmes and Durian, 1999) or by a vane method (Davis et al., 2004). The yield stress is defined as: τc = γc • G’0 (eq. 2) where τc is the yield stress, γc the yield strain and G’0 the foam storage modulus in the linear viscoelastic regime of the foam (Saint-Jalmes and Durian, 1999). The crossover of G’ and G’’, i.e. the strain for which G” starts to dominate G’, can also be defined as the yield strain.

It is known that the foam storage modulus G’ depends on the foam structure: ’ ∝ (ɸ) (eq. 3) where σ is the interfacial tension, R the bubble radius, and (ɸ) a decreasing function of the liquid fraction (Princen, 1983; Saint-Jalmes and Durian, 1999; Marze et al., 2009).

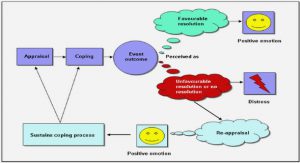

The foam structure can be destabilised by processes such as drainage, coalescence or disproportionation. Coalescence and disproportionation are gathered under the term “coarsening” in

Fig. II.5 (Dollet and Raufaste, 2014). Foam drainage is the flow of liquid under the influence of gravity through the network of films and Plateau borders. Coalescence is the fusion of two bubbles after the rupture of a lamella separating them. Disproportionation is the surface-tension-driven gas exchange from small to large bubbles due to the difference in internal pressure (Laplace’s law eq. 1). Drainage leads to a drier foam (a decrease of the foam liquid fraction φ) whereas coalescence and disproportionation both lead to larger average bubble size or coarsening, although with a different distribution of sizes (Hutzler and Weaire, 2000; Koehler et al., 2000; Stevenson, 2012; Cantat et al., 2013).

Fig. II.5 The interdependence of bulk foam rheology and instability mechanisms (Hilgenfeldt et al., 2001)

Due to these multiple ways of destabilisation, it is difficult to obtain stable liquid foams and the use of surfactants is crucial for this purpose.

Stabilising agents and their contribution to foam properties

Aqueous foam stabilisation can be partly achieved by the adsorption of stabilising agents at the air-water interface. They lower the interfacial tension, change the rheological properties of the interface and may provide repulsive forces between bubbles, thereby increasing the disjoining pressure. In addition, some of them can increase the bulk viscosity (Cantat et al., 2013).

Different agents can be used, Low Molecular Weight (LMW) surfactants and macromolecules (Fameau and Salonen, 2014). LMW surfactants can be ionic or non-ionic. Sodium Dodecyl Sulfate (SDS), an ionic surfactant, is commonly studied in theoretical foam models. For food applications, mono and diglycerides, fatty acids, and esters are used (Gaupp and Adams, 2007; Moonen and Bas, 2007). Macromolecules such as polymers and proteins can also be used, as well as solid particles agents. Proteins, polymers and LMW surfactants can be used simultaneously in complex systems, in particular for food applications.

LMW surfactants, an easier system than proteins, are widely used to understand the general mechanisms underlying foam stability. Thus, the main notions and concepts about aqueous foams stabilised by LMW surfactants will be first presented. Then, we will focus on protein foams.

LMW surfactants and foam stability

Fig. II.6 Gibbs-Marangoni effect (Salager and Choplin, 2008)

The stability against drainage can be increased by higher bulk viscosity and smaller bubbles radius. Liquid flow inside Plateau borders during drainage shears the liquid-gas interface transversally to the flow direction. Leonard and Lemlich have modeled the flow through single Plateau borders and have shown that the drainage rate depends on a mobility parameter M defined as: = • (eq. 4) s where μ is the bulk viscosity, r the Plateau border size and μs the interfacial shear viscosity.

A lower mobility reduces drainage rates (Leonard and Lemlich, 1965; Saint-Jalmes et al., 2004; Rio et al., 2014).

Coalescence is the least understood of the instability mechanisms. The mechanism of stabilisation by LMW surfactants is linked to their ability to resist interfacial tension gradients. The film elasticity is governed by the fast kinetics of exchange with the bulk (Fig. II.6) (Salager and Choplin, 2008). Some authors report that coalescence in foams occur more likely at a low critical liquid fraction (Carrier and Colin, 2003). Other studies on isolated films have shown than the rupture of isolated films, similar to the coalescence process, is controlled also by the dilatational elastic modulus and depends on the pressure applied on the film (Georgieva et al., 2009). In addition, T1 events may also result in film rupture due to insufficient bubble surface coverage by the surfactant and a small ratio of interfacial dilatational viscosity to interfacial tension (Carrier and Colin, 2003; Drenckhan and Langevin, 2010; Biance et al., 2011).

An increase in the bubble radius and a decrease in gas solubility in water (such as with nitrogen gas) can reduce the disproportionation rate (Weaire and Pageron, 1990; Hilgenfeldt et al., 2001). The higher the dilatational elastic and viscous moduli, the lower the disproportionation rate (Kloek et al., 2001; Georgieva et al., 2009). In addition, very closely packed monolayers act as gas barriers (Rio et al., 2014). Bulk viscosity can also reduce the disproportionation (Kloek et al., 2001).

However, the foam stability is still a source of many open questions. Film dynamics are believed to have a central role. If one film ruptures, the system has to rearrange, which affects the properties of the remaining films. Interestingly, T1 events may be triggered by instability mechanisms such as disproportionation (Gopal and Durian, 1999; Höhler and Cohen-Addad, 2005). Since T1 events may also result in film rupture, their study could be a new route toward an understanding of coalescence, complementary to the methods based on isolated foam films (Rio and Biance, 2014). Most of the studies on this subject have been performed with LMW surfactants. As far as we know, only one study has been performed with proteins, but in mixture with a polysaccharide co-surfactant (Durand and Stone, 2006).

T1 events are also involved in foam rheology (Gopal and Durian, 1999; Höhler and Cohen-Addad, 2005; Dollet and Raufaste, 2014). In other words, the film dynamics prominently contribute to the mechanical properties and to the stability of liquid foams and have not yet been studied for proteins.

The characterisation of the interfacial properties of proteins is needed to understand their aptitude to stabilise foams.

Interfacial properties of proteins

Interfacial characteristics correspond to, for instance, interfacial tension, amount of adsorbed proteins, conformational changes or interfacial rheological properties (Rodriguez Patino et al., 2008). It should be noted that interfacial properties do not account for the bulk properties (proteins remaining in solution) and that a single planar interface air/water is characterised.

Proteins are amphiphilic macromolecules, which adsorb to hydrophobic interfaces and decrease the interfacial tension. When the protein concentration at the interface is sufficient for the building of interactions between adsorbed proteins, a visco-elastic interfacial film is formed (Graham and Phillips, 1978; Croguennec et al., 2006).

The rate of protein adsorption is the most important factor in foam formation (or foamability), defined as the capacity of a protein solution to produce foams. An efficient foamability is a prerequisite for the study of the foam stability. Protein adsorption to the air/water interface is thermodynamically favorable, due to the dehydration of hydrophobic groups of the protein upon adsorption at the interface. It takes place in four successive steps: i) lag period, ii) diffusion of the protein molecules to the interface, iii) protein adsorption and iv) protein structural rearrangements. The adsorption rate depends on protein characteristics such as the net charge, the molecular size, the surface hydrophobicity, the chemical reactivity and the protein concentration. Even if a high surface hydrophobicity promotes the protein anchoring, the molecular size, net charge and flexibility can be more relevant (Damodaran, 2005). The adsorption of a protein determines the rate of surface tension decrease (Macritchie, 1978; Borcherding et al., 2009; Wang et al., 2016).

The mechanical properties of the interfacial film are correlated with foam stability (Prins and van Kalsbeek, 1998). The interfacial rheology describes the response of the interfacial film to the deformation. Two kinds of deformation may be applied: area changes by dilatation/compression and shape changes by shearing (Rodriguez Patino et al., 2008).

The interfacial shear rheology is sensitive to changes in the strength of the molecular interactions within the interfacial film and to the macromolecular structure. Generally, interactions between the adsorbed molecules confer a cohesive structure with high shear moduli to the interfacial film (Ridout et al., 2004; Caetano da Silva Lannes and Natali Miquelim, 2013).

The interfacial dilatational rheology is sensitive to the adsorption/desorption kinetics of surfactants. However, proteins do not readily adsorb and desorb during compression-expansion cycles. Thus, the interfacial dilatational moduli are related to intermolecular interactions as well as to the dynamics of protein conformation (Graham and Phillips, 1980; Cascão Pereira et al., 2003b).

According to these authors Bos and van Vliet, (2001), Table II.1 compares the main interfacial features for proteins and LMW surfactants. It should be noted that it does not account for exceptions.

Proteins may undergo conformational changes, self-assemble and form multilayers at the interface. This feature makes the relationship between interfacial concentration and interfacial tension more complex, and discriminates proteins from LMW surfactants. In contrast with LMW surfactants, protein adsorption at the interface can be considered almost irreversible, due to the large number of adsorbed protein segments at the interface. Thus, interfacial protein self-assembly and quasi-irreversibility of the adsorption may result in low-frequency interfacial shear and dilatational elasticity, while the dilatational elasticity observed with LMW surfactants is governed by the kinetics of exchange with the bulk (Bos and van Vliet, 2001). Thus, interfacial films for proteins are out-of-equilibrium and strongly time-dependent, whereas LMW surfactants quickly reach an equilibrium state at the interface (Bos and van Vliet, 2001).

In this thesis, we will focus on protein foams, in particular whey proteins, due to their sensitivity to environment and processing. Indeed, physical as well as chemical modifications induce changes in dairy protein structure and hence their interfacial and foam properties.

Protein structure

With a focus on dairy proteins specificities, general aspects of biochemical and physicochemical properties of proteins will be presented.

Proteins and their sensitivity to environment and processing

Protein structure can be characterised at different levels (Fig. II.8) (Garrett and Grisham, 2008):

– Primary structure: sequence of amino acid residues linked with covalent peptide bonds

– Secondary structure: spatial arrangements of the polypeptide chain (helices, β-sheets, random coil structures…)

– Tertiary structure: assembly of secondary structures which constitutes the three-dimensional conformation

– Quaternary structure: non-covalent assembly of monomers.

Fig. II.8 Protein structure (a) polypeptide chain. R corresponds to the side chains of the amino acids. The side chains of the amino acids R can be reactive in particular lysine and cysteine (Walstra et al., 1999) (b) α-Helix structure (Garrett and Grisham, 2008) (c) schematic representation of the three-dimensional structure of β-lactoglobulin. Disulphide bonds are represented in yellow and individual β-strands forming β-sheets are identified with a letter (Ikeguchi, 2014).

The information for the folding of the protein is contained in the polypeptide chain. A globular protein structure with a hydrophobic core, such as for β-lg, ovalbumin or lysozyme, is formed if there are sufficient hydrophobic residues. Intrinsically disordered proteins such as ovomucin or β-casein are less structured than globular proteins due to the abundance, in the case of caseins, of proline residues, unfavourable to secondary structuration, and to the lack of intramolecular disulphide bonds (S-S). Indeed, disulphide bonds, serve as an energy barrier for the rearrangement of the peptide chains and reduce the conformational changes (Horiuchi et al., 1978; Thornton, 1981; Walstra et al., 1999).

Proteins are sensitive to their local environment, especially due to the weak interactions (hydrogen bonds, hydrophobic interactions, electrostatic bonds and van der Waals forces) which stabilise their secondary, tertiary and quaternary structure. For this reason, the protein isoelectric pH (pI) is an important physico-chemical characteristic. At the pH=pI, the protein net charge is equal to zero and the protein−protein interactions are attractive. Below or above the pI, the protein net charge is respectively positive or negative, leading to electrostatic repulsion (Engelhardt et al., 2013). As discussed previously in section 1.2.2, the protein net charge contributes to the protein adsorption at the air/water interface. We will see that the protein net charge is also a lever for the separation of dairy proteins and for the production of varied protein structures.

Heat treatment can disrupt the weak non-covalent interactions (hydrogen bonding and electrostatic interaction) involved in the secondary and tertiary structure, and induces a partial, possibly irreversible protein unfolding, resulting in the exposition of hydrophobic groups to the solvent. The loss of secondary structure leads to an irreversible denaturation, because of the new bonds created with the surrounding water. Previously buried hydrophobic groups become exposed. Aggregation may follow due to intra and intermolecular interactions by hydrophobic and electrostatic interactions, as well as sulfhydryl/disulphide interchange upon prolonged heating. Indeed, a free cysteine thiol can react with another cysteine previously involved in a disulphide bond, resulting in the interchange of one of the cysteine moieties of the bond. After the interchange, the new bond may link two distinct protein molecules. It should be noted that the free sulphydryl group, from β-lg, exposed upon heating, is likely to be involved in sulfhydryl/disulphide interchange (Garrett and Grisham, 2008; Wijayanti et al., 2014; Anema, 2014).

The heating mode of proteins, either in solution or in the powder state (dry-heating), influences the extent of denaturation and aggregation.

Dry-heating is currently not commonly used for whey protein powders, but is widely applied on egg-white protein powders to maintain their microbiological quality and for the improvement of their foaming properties (Baron et al., 2003; Kato et al., 1989; Van der Plancken et al., 2007a; Desfougères et al., 2008; Talansier et al., 2009; Boreddy et al., 2016). In comparison with heating of solutions, dry-heating of protein powders is a way to disjoin protein denaturation and aggregation. Generally, powders have a low moisture content. Water may be either linked to the powder components (proteins, sugars) or free. The powder stability depends on free water, which is available for chemical reactions. This water availability can be measured through water activity (aw) (Mathlouthi, 2001). Thus, aw is governed by moisture content, product chemistry and structure, and storage conditions (Stapelfeldt et al., 1997). Due to the low water activity aw of powders, proteins are more stable as regards heat denaturation in the powder state than in solution. For instance, the denaturation temperature of β-lactoglobulin is 167 °C in the powder state (aw 0.23) and 78 °C in solution (Zhou and Labuza, 2007; Rao et al., 2016). Thus, dry-heating may preserve the structure in comparison to solution (Morgan et al., 1999a; Báez et al., 2013).

Dry-heating of proteins in the presence of sugars (naturally present or added) is an efficient way to produce glycated proteins by the Maillard reaction. Glycation in the dry-state prevents to some extent both the protein denaturation and aggregation which occur in solution (Báez et al., 2013). The first step is the condensation of an available amino group and a carbonyl-containing moiety (usually a reducing sugar) to form a Schiff base and an Amadori product (Fig. II.9). Later stages produce advanced-glycation end-products characterised by a browning colouration. The consequences of Maillard reaction can be positive (development of flavours) or negative (unwanted coloration changes and loss of the protein bioavailability) (Liu et al., 2012; Dyer et al., 2016; Milkovska-Stamenova and Hoffmann, 2016; Arena et al., 2017).

Dairy proteins

Whey proteins

All the whey proteins, except proteose peptone which are soluble casein fragments, are globular proteins.

β-lactoglobulin is the main whey protein in bovine milk. It contains two intramolecular disulphide bonds and one free sulphydryl group (SH) per monomer. The latter is highly reactive upon heat treatment. β-lg is a highly structured, very compact globular structure, with 43 % β-sheets (Fig. II.8c). The quaternary structure of β-lg depends on the solution pH: monomer (pH<3.5 and pH>7.5), dimer (5.5<pH<7.5) or octamer (3.5<pH<5.2) (Fox and McSweeney, 2003). The hydrophobic core, delimited by β-sheets, can bind apolar ligands such as retinol.

α-lactalbumin is the second most prevalent protein in whey. It carries four intramolecular disulphide bonds, but does not contain any free sulphydryl group. α-la naturally forms intramolecular ionic bonds with Ca2+, which make the molecule resistant to thermal unfolding. However, a low pH (pH<5) induces the loss of the Ca2+ ligand and lowers the heat stability (Walstra et al., 1999).

Caseins

Caseins are intrinsically disordered proteins. They exist in large dynamical aggregates in milk, called the casein micelle (Fig. II.10). They have only short helix segments and little tertiary structure. Thus, in solution, caseins are partly unfolded and many hydrophobic groups are exposed. The micelle is stabilised by hydrophobic bonds and salt bridges involving colloidal calcium phosphate. Reducing the pH of milk from 6.7 to 4.6, at the isoelectric pH of caseins, induces a solubilisation of the colloidal calcium phosphate and the precipitation of caseins. Thus, caseins are not soluble at their pI. However, compared to whey proteins, caseins are stable to heating, even if a lower pH diminishes the heat stability (Fox and McSweeney, 2003).

Fig. II.10 Structure of casein micelle (Ortega-Requena and Rebouillat, 2015)

Finally, whey proteins, due to their globular structure are sensitive to heat and remains soluble at the isoelectric pH, whereas caseins, highly disordered proteins, are stable to heating and become insoluble at the isoelectric pH. For this reason, the precipitation of caseins at pH 4.6 is commonly used in many milk processing protocols in order to separate them from whey proteins (Walstra et al., 1999).

Heat treatments of whey proteins and foam properties

Heating of whey proteins is a common processing operation for changing functional properties (e.g.

gelling, emulsion or foam stability) (Anema, 2014; Guyomarc’h et al., 2015).

Heating in solution

The heating of β-lg in solution induces different structural changes, such as the decrease in the α-helix content, the increase in random coils and the increase in surface hydrophobicity, which deeply impact the interfacial properties (Kim et al., 2005).

Fig. II.11. Whey protein aggregates, adapted from Nicolai and Durand (2013). Strands are produced under high electrostatic repulsion between proteins (above or below the pI at low ionic strength), whereas spherical particles are produced under attractive condition between proteins (at the pI, or above or below the pI at high ionic strength).

A considerable amount of research has been conducted on the denaturation/aggregation of whey proteins in solution. Different kinds of protein aggregates are obtained, with well characterised structures and physicochemical properties depending on the protein net charge, which depends on pH, and ionic strength (Fig. II.11). Primary aggregates constitute the building blocks of larger aggregates. Two types of primary aggregates exist, strands (strong electrostatic repulsion between the proteins) and spherical aggregates (for pH close to pI). Secondary aggregation of the strands and the spherical particles occurs at higher aggregate concentrations and longer heating time, until the formation of a gel or a precipitate (Nicolai and Durand, 2013). Schmitt et al. (2014); Lazidis et al. (2016) have demonstrated that WPI microgels greatly improve foams stability through a reduced drainage. Fibrils are another type of aggregates, formed in acidic condition (pH < 2.5) at low ionic strength and longer heating time. The structure involves peptides resulting from protein hydrolysis (Nicolai and Durand, 2013). Oboroceanu et al. (2014) have shown that fibrils could be also an interesting foam stabiliser, as effective as egg-white proteins which are the reference foaming protein food ingredient.

Powder dry-heating

Since dry-heating is currently not commonly used for whey protein powders, but is widely applied egg-white protein powders, this part will focus on the dry-heating of whey proteins powders and some knowledge about egg-white dry-heating will also be mentioned.

It has been reported that dry-heating or in-solution heating generate distinct structure modifications of proteins (Báez et al., 2013; Gulzar et al., 2013). Whey protein dry-heating induces chemical modifications, such as hydrolysis, dehydrations, deamidation, (Gulzar et al., 2011b, 2011a, 2013), or conformational changes (Radwan et al., 1993; Morgan et al., 1999a; Báez et al., 2013). Extensive dry-heating conditions lead to possibly insoluble aggregates by intramolecular and intermolecular cross-linking and oxidation of sulfhydryl groups (Gulzar et al., 2011b). Due to the presence of lactose in whey protein ingredients, Maillard reaction is a relevant phenomenon when they are subjected to heat treatment, drying or storage (Fenaille et al., 2004).

Dry-heating parameters, such as the temperature and duration of dry heating, the pH prior to dehydration, the lactose content, the powder aw change the nature and the extent of these chemical modifications.

Usually, molecular motion is reduced in powders because of their amorphous glassy state at room temperature. The glass transition temperature Tg corresponds to the change from amorphous glassy state to the rubbery state, in which the inter-chain mobility increases and makes chemical reactions possible. The increase of the powder aw and sugar content decreases the Tg (Sherwin and Labuza, 2003; Thomas et al., 2004; Zhou and Labuza, 2007). Thus, chemical reactions such as denaturation or lactosylation may occur at a lower temperature. As an example, the denaturation temperature of proteins in a WPI powder is 175 °C, 163 °C and 132 °C at aw 0.11, 0.23, 0.53 respectively (Zhou and Labuza, 2007). Thus, monitoring of the dairy powders aw is crucial. For instance, nearly all the β-lg is lactosylated after one week of storage (aw 0.45, 37 °C) (Thomas et al., 2004). An optimum aw for the Maillard reaction was reported to be in the 0.5 to 0.8 range (Liu et al., 2016).

An influence of pH prior to dehydration on dry-heating effects has already been observed. The rate of β-lg lactosylation is significantly lower at pH 5 than at pH 7 (Thomsen et al., 2012). Other authors have claimed that the rate of aggregation of WPI in the dry state was lower with decreasing pH (pH 2.5, 4.5 and 6.5) (Gulzar et al. 2011b). Guyomarc’h et al. (2015) suggested the extent of lactosylation of WPI at pH 2.5 is a limiting factor of the Maillard reaction, which could explain the lower rate of aggregation at pH 2.5 as compared to pH 6.5. Famelart et al. (2018) have shown the formation of microparticles by WPI dry-heating at pH 9.5. Desfougères et al. (2011) have shown that the dry-heating of lysozyme at pH 3.5 forms more succinimide derivatives than at pH 7.0 and pH 8.5.

Dry-heating at low temperature (under 70 °C) induces intermediate levels of protein denaturation and could preserve the structure of whey proteins (Gauthier et al., 2001). The loss of protein solubility is time/temperature dependent (Van der Plancken et al., 2007). The rate of lactosylation is increased with temperature and time (Thomsen et al., 2012). The extent of lactosylation depends on the protein, sugar concentrations and thermal treatment (Milkovska-Stamenova and Hoffmann, 2016).

Studies about the effect of dairy powder dry-heating on foaming properties are listed Table II.2. Some studies have demonstrated that dry-heated dairy powder exhibit enhanced foam stability (Radwan et al., 1993; Medrano et al., 2009; Hiller and Lorenzen, 2010a; Báez et al., 2013). Glycation may increase the thickness and viscoelastic properties of the interfacial layer, and improve water holding capacity of proteins (O’Mahony et al., 2017). In contrast, Báez et al. (2013) have shown that the β-lg foam stability is higher after pre-heating in solution (85 °C , 3 min) than after dry-heating, and that glycation by glucose either in the dry-stated or in solution does not improve foam properties. The effects of glycation on foam properties are complex, as they depend on protein structure (globular, disordered), nature of the carbohydrate, experimental conditions (thermal treatment, powder aw) and foam formation mode (whipping, bubbling) (O’Mahony et al., 2017).

In the following section 3, we chose to present the literature about the relationships between whey protein structure, interfacial properties and foaming, by pairs, in order to shed light on the complexity of interpretation and the discrepancies between studies. It should be noted that available literature data on whey protein film dynamics are scarce, and therefore cannot be discussed in this section.

Multiscale approach about whey proteins foams

We chose to focus on the relationships between whey protein structures, interface and foam properties because whey proteins are the object studied in the thesis. However, some generalities about protein foams can also be mentioned.

The relationships between protein structure and foam properties are complex. The presence of whey protein micro-gels (specific aggregates presented in section 2.2.3) has been reported to have a positive influence on foam stability (Schmitt et al., 2014; Lazidis et al., 2016). Aggregates have to be small enough to be gelled in the liquid films in order to stabilise foams (Rullier et al., 2009). Due to their elasticity, gels may limit or arrest both drainage and disproportionation (Fameau and Salonen, 2014). Aggregated proteins, depending on the structure and the size may also slow down the drainage by confinement in the Plateau borders (Rullier et al., 2008). Indeed, aggregates can be blocked inside the liquid film and increase the viscosity, leading to a reduced drainage (Fameau and Salonen, 2014). Lexis and Willenbacher (2014b), suggest that a network can be formed across the liquid film. Aggregates could be involved in the liquid film network and increase foam stability and bulk rheology. Interestingly, Dombrowski et al. (2016) have shown that aggregates, due to their surface hydrophobicity, molecular flexibility and zeta potential, may also improve foam stability by their presence at the interface.

In contrast, others authors shown that aggregates may decrease the foam stability and yield stress (Davis and Foegeding, 2004; Rullier et al., 2008; Dissanayake and Vasiljevic, 2009). The aggregate size and the balance between non-aggregated and aggregated proteins should be taken into account (Zhu and Damodaran, 1994; Rullier et al., 2008). Non-aggregated proteins contribute to the foam formation and stability because they adsorb quickly and saturate the interface even if their respective concentration in the bulk is minor. The foam formation is improved for a monomers to aggregates ratio of 60:40. In contrast, a higher foam stability was obtained for a 40:60 ratio (Zhu and Damodaran, 1994).

A high foam overrun and lower drainage rate was found for hydrolysed WPI and β-lg (Ipsen et al., 2001; Tamm et al., 2012). Conformational changes and partial unfolding of whey proteins may improve their foam stability, mainly through changes in their interfacial properties (Croguennec et al., 2006; Dissanayake and Vasiljevic, 2009). Some studies have demonstrated that glycated proteins, obtained by powder dry-heating, exhibit an enhanced foam stability (Medrano et al., 2009; O’Mahony et al., 2017).

Engelhardt et al. (2013) have shown that the β-lg net charge has a determinant influence on the bulk foam rheology. Foams have higher yield stress and storage moduli at the pH=pI, where the net charge is zero.

Relationships between whey protein structure and interfacial properties

The interfacial properties are sensitive to the structure of proteins adsorbed at the interface. Dilatational interfacial rheology of protein films are affected by the intra-protein rigidity. β-casein, a flexible protein, exhibits a low dilatational surface elasticity. In contrast, β-Lg, a rigid protein, shows higher dilatational modulus (Graham and Phillips, 1980). Ridout et al. (2004) have shown that caseins in mixture with β-lg deeply decrease both the dilatational and shear interfacial elasticity. Caseins have a faster adsorption at the interface and easily unfold at the interface due to their flexible structure (Graham and Phillips, 1980). Note that whey proteins ingredients also contain residual non-micellar caseins (Coppola et al., 2014). Thus, the casein content in whey protein ingredients can be determinant for their interfacial properties, due to the capacity of casein to saturate the air/water interface.

A study from Mackie et al. (1999) shows a different interfacial behaviour between the A and B genetic variants of β-lg, as regards the interfacial tension and dilatational modulus, whereas they differ only by two amino acids. In addition, Engelhardt et al. (2013) have shown that the β-lg net charge has a determinant behaviour for the interfacial rheology. At the pI, disordered β-lg multilayers, with high interfacial dilatational elasticity, are formed at the air-water interface, whereas, below and above the pI, lower interfacial dilatational elasticities are observed due to the protein repulsion within the adsorbed layer.

Croguennec et al. (2006) have shown that modified β-lactoglobulin, which exhibits higher surface hydrophobicity and a slight modification in the tertiary structure, adsorbs faster at the air/water interface than the native form, forming a denser protein layer. They also suggested that the β-lg free sulfhydryl is involved in the interfacial shear rheology.

As regards the effect of β-lg glycation on the adsorption rate and dilatational modulus at the air/water interface depends on the nature of the carbohydrate and the experimental conditions (thermal treatment, powder aw) (Corzo-Martínez et al., 2012; Medrano et al., 2009).

Interestingly, Jung et al. (2010) have found that peptides formed during heating of a β-lg solution at pH 2.0 have markedly changed interfacial properties, consisting in higher surface activity and increased shear viscoelastic properties. In contrast, the enzymatic hydrolysis of purified β-lg decreased both the interfacial shear elasticity and viscosity values (Ipsen et al., 2001).

Mahmoudi et al. (2010) showed that WPI aggregates did not change the interfacial dilatational properties in comparison with native WPI, whatever the size and structure of the aggregates. In contrast, Dombrowski et al. (2016), after removing the non-aggregated proteins, have shown that β-lg aggregates change interfacial properties. Aggregates with a higher size, characterised by a higher electrostatic repulsive force and a lower flexibility, decrease the diffusion rates to the interface and are less effective to decrease the interfacial tension. These authors observed a significant increase of the dilatational storage modulus E’ with aggregate size, attributed to an increase of hydrophobicity and steric interactions.

Table of contents :

Chapter I General introduction and strategy

1. Industrial context

2. Strategy and research question

3. References

Chapter II Bibliography

1. Aqueous foams

1.1. Foam structure and structural changes due to destabilisation processes

1.2. Stabilising agents and their contribution to foam properties

2. Protein structure

2.1. Proteins and their sensitivity to environment and processing

2.2. Dairy proteins

3. Multiscale approach about whey proteins foams

3.1. Relationships between whey protein structure and foam properties

3.2. Relationships between whey protein structure and interfacial properties

3.3. Relationships between whey protein interfacial and foam properties

4. References

Chapter III Materials and Methods

1. Materials

2. Preparation of dry-heated powders

2.1. Sample preparation

2.2. Experimental design

3. Structural properties

3.1. Size-exclusion high-performance liquid chromatography

3.2. Reversed-phase high-performance liquid chromatography

3.3. Mass spectrometry

4. Foam properties

4.1. Foam formation and drainage rate

4.2. Foam formation and rheometry

5. Interfacial properties

5.1. Dynamic drop tensiometry and interfacial dilatational rheometry

5.2. Shear interfacial rheology

6. Film dynamics

7. Statistical analysis

7.1. Principal Component Analysis

7.2. Analysis of Variance

7.3. Tukey contrast

7.4. Spearman correlations

8. References

Chapter IV Screening of dry-heating parameters and characterisation of the foam stability against drainage

1. How foam stability against drainage is affected by conditions of prior whey protein powder storage and dry-heating: a multidimensional experimental approach

1.1 Introduction

1.2 Materials and Methods

1.3 Results

1.4 Discussion

1.5 Conclusions

1.6 Acknowledgements

1.7 Supplementary data

2. Complementary studies

2.1 Observation of coalescence avalanche

2.2 Interfacial shear rheology

3. References

Chapter V Structural consequences of whey protein dry-heated under controlled physicochemical conditions and relationships with foam stability

1. Structural changes of whey proteins upon dry-heating under controlled physicochemical conditions and relationships with foam stability

1.1. Introduction

1.2. Materials and Methods

1.3. Results

1.4. Discussion

1.5. Conclusions

1.6. Acknowledgements

1.7. Supplementary data

2. Complementary studies

2.1. Mass spectrometry of pre-conditioned WPI

2.2. Mass-spectrometry of pre-conditioned β-lg

3. References

Chapter VI Interfacial properties, film dynamics and foam properties: a multi-scale approach to dairy protein foams

1. Interfacial properties, film dynamics and bulk rheology: a multi-scale approach to dairy protein foams

1.1. Introduction

1.2. Materials and Methods

1.3. Results

1.4. Discussion

1.5. Conclusions

1.6. Acknowledgements

1.7. Supplementary data

2. Complementary studies

2.1. Disproportionation exponents

2.2. Differential effect on protein aggregation for β-lg and WPI

2.3. Interfacial properties and stability against drainage of foams obtained by bubbling

2.4. Interfacial and foam properties: comparison with surfactant and protein controls

3. References

Chapter VII General discussion & perpectives

1. Discussion

1.1. Une approche multifactorielle pour contrôler et exploiter la variabilité

1.2. De petites modifications structurales des protéines induisent des changements radicaux des propriétés interfaciales et moussantes

1.3. Rhéologie interfaciale et dynamique des mousses

1.4. La rhéologie des mousses, une méthode plus sensible à la rhéologie interfaciale que l’étude du

drainage

1.5. Spécificités des mousses de protéines et importance de la dynamique

1.6. Multi-dimensionnalité des propriétés des mousses et impact des procédés

2. Perspectives

2.1. L’étude des T1, une voie originale pour la caractérisation des mousses de protéines

2.2. Pour aller plus loin dans les mécanismes liés aux procédés

2.3. Applications industrielles

3. Conclusions

4. Références