Get Complete Project Material File(s) Now! »

Encapsulation yield and preparation conditions

Several methods for the encapsulation of molecules in liposomes have been proposed. Some are compatible with the manipulation of proteins, while others not due to the use of solvents or inadequate temperatures (see section 2.4.4 Other procedures below). One important parameter is the encapsulation yield. As mentioned in the introduction, the processed molecules may include proteins produced in low amounts (≤ 2 mg) and/or difficult to concentrate in aqueous solution (≥ g/L). Preparation procedures of large unilamellar vesicles will be reviewed with this constraint of a need for a high encapsulation yield in mind.

The film hydration method

The film hydration method relies on the hydration of a preformed lipid film with the solution to encapsulate. The film is made by the evaporation of a solution of lipids in organic solvents, like methanol or chloroform. While these solvents may be harmful, extensive drying of immersed in a solution containing the molecule to encapsulate. Spontaneously or mechanically, the film detaches to form vesicles, entrapping the surrounding solution. the film gets rid of all of them. The dried film is hydrated with a solution of the molecule to encapsulate. The concentration of the lipid is generally in the range of 1–10 g/L. The steps involved in film hydration may include suspension shearing, freeze/thaw cycles, sonication, heating and extrusion on a syringe filter [105–107]. The techniques relying on freeze/thawing, sonication and heating are not adapted to our application due to the risks of protein denaturation.

As illustrated on figure 2.33, not all the engaged solution is encapsulated in the vesicles, leading to a limited encapsulation yield. In a typical experiment, where 200 nm sized DOPC liposomes are prepared, with lipid concentration of 10 g/L, the encapsulation yield is at best 8 % (see appendix C.4.1, p. 200). This technique has however the main advantage of being compatible with mild handling conditions.

An encapsulation yield as high as 50 % can be reached under certain conditions. If the molecule to encapsulate can be made to have some affinity for the lipid membrane, up to half the initial amount of protein may stay in the liposome, while the other half will be attached onto the outer leaflet and removed during the liposome isolation step. This technique has been applied to the encapsulation of superoxide dismutase in liposomes made of DPPC:cholesterol [108] or trypsin in DPPC:cholesterol:dicetyl phosphate liposomes [109]. Depending on how the protein is retained on the interface, the encapsulation yield may depend on the pH or the ionic strength of the solution, e.g. in the case of electrostatic interactions.

Release mechanisms and associated timescales

In this chapter, we presented light-sensitive liposomes with various release properties. Concerning the release time, a broad range is covered and ranges from the microsecond to several hours. We are interested in fast releasing systems, with a characteristic time below the second. Only two systems amongst the reported ones reach this criterion: the first one is based on the permeabilization of the membrane and the other one on the disruption of the membrane.

The first system family relies on the increase of permeability of the lipid bilayer. It is possible to release small hydrophilic molecules, but nothing has been shown on the release of proteins. In fact, they may not be able to cross the membrane at all, due to their size, their ionization state and their hydrophilicity. Slightly hydrophobic molecules have been reported to stay stuck in the lipid bilayer. Therefore, this system is not adequate to the release of proteins. For these objects to escape, nanometer sized holes must be created in the lipid bilayer.

Micro- and nanometer-sized hydrogels

The second candidate for protein release in cell culture media are micro- or nanometric sized hydrogels, referred to as nanogels in this document. These systems are constituted of a hydrophilic polymer matrix entrapping an aqueous buffer and the molecules of interest. As the major constituting part of those gels is water, the conditions are adequate for the entrapment of peptides and proteins. Three main mechanisms of release are reported in the literature for the release of molecules: passive diffusion, gel destruction and gel collapse (see figure 3.1). Passive diffusion will not be considered here, as it opposes to triggered release. It must be avoided and can be if the mesh size of the gel network is smaller than the size of the entrapped proteins. Entrapped molecules can be released from this tight network by breaking the gel apart. Similarly, stimuli-induced gel collapse leads to the expulsion of the entrapped content. This is presumably due to a fracturing of the network during the shape/volume transitions.

Nucleid-acid based hydrogels

Recently a hydrogel encapsulation system made of plasmids crosslinked with ethylene glycol diglycidyl ether (EDGE, a di-epoxide) was reported. The gel self-disassembles upon blue light irradiation (400 nm, unknown power), which releases both entrapped material and the plasmid itself. The mesh size of the system has been characterized experimentally and is in the range of 30–40 Å. The release of the plasmid occurs within 500 hours, with the entrapped material, such as BSA, lysozyme or FITC-dextran (77 kg/mol). The timescales associated with the release depends on the entrapped molecules 200 hours are reported for BSA and dextran, while 48 hours are for lysozyme [143, 144]. The hydrodynamic radius of the lysozyme is ≈ 16 Å, smaller than the mesh size, while the radius of BSA is ≈ 35 Å and the one of the dextran 55 Å; this explains why the release of lysozyme is faster than the other molecules. However, the comparison with the other systems is not obvious, as the gel particles are macroscopic (millimetric). The mechanism of degradation suggested by the authors is the self degradation of ethers in water under light irradiation. Linked to nucleic acid, the wavelength of maximum degradation efficiency is 400 nm.

Encapsulation yield and loading constraints

Impact of the synthesis procedure on the protein encapsulation Several methods have been reported for the synthesis of the nanogels [155]:

Micromolding The monomers or the polymer chains are molded in a PDMS matrix. Particles as small as 100 nm have been reported. While it is possible to obtain arbitrary shapes with this method, the “2D” synthesis limits the throughput of the gel production.

Reverse emulsion The gels can be prepared from the emulsion of an aqueous phase containing the monomers and the molecule to encapsulate, dispersed in an oil phase.

The size of the emulsion fixes the size of the nanogels. Several methods have been proposed to prepare the emulsion: surfactants+ultrasounds, microfluidic devices and injection of the aqueous phase in the oil through a porous membrane.

Homogeneous polymerization The monomers and a polymerization initiator can be dissolved in an aqueous medium. The gels will grow from a nucleation point, until the polymerization is stopped (either by lack of monomers or by losing the reactivity).

At the exception of the technique relying on ultrasounds, all of them are a priori compatible with the process of proteins.

The molecules of interest are loaded in the gel either during its synthesis or after. For the emulsion-based procedures, the protein can be added to the emulsified aqueous phase. Unless the protein is excluded from the matrix during the polymerization, high encapsulation yields are expected; the same is expected for the molding process. For the homogeneous polymerization, the protein can also be added to the reaction mixture. If no specific affinity is developed between the encapsulated molecule and the matrix, the encapsulation yield is limited by the volume fraction of the aqueous phase actually included in the matrix. If the mesh size of the gel permits it, the protein can also be entrapped in the gel after its synthesis; the role of the size mesh will be discussed further in this section.

Concerning the synthesis conditions, all the systems reported in the previous section are made by radical polymerization. Adding the protein in this step is questionable, as the protein activity can be damaged by radicals [156]. The damages are particularly important in presence of oxygen, and include protein cross-linking (via the histidine residues), protein fragmentation, protein oxidization and protein unfolding.

Preparation conditions and encapsulation yield

Several techniques are reported, enabling to control the size of the polymersomes and the encapsulation yield1. Some techniques are based on organic solvents. One of the most reported method relies on dissolving the polymer in an organic solvent. The aqueous solution to encapsulate is added dropwisely to the organic solvent, yielding vesicles whose size is in the 100 nm – 3 μm range. Details on the other techniques are available in references [190–192]. Not compatible with the handling of proteins, they will not be discussed here.

The lipids can be dissolved in a volatile solvent and made to dry on a flat surface to make a polymer film [190]. Upon hydration, vesicles in the 50 – 800 nm range are formed; monodisperse objects of a defined diameter can be obtained by extrusion through a filter.

The size of the filter pores defines the size of the obtained polymersomes. Electroformation applied to the polymer film will lead to micrometer-sized polymersomes. However, low encapsulation yields are expected. Similar to the techniques used for the preparation of liposomes, yields in the 10 % range are expected.

Several case of self-assembly of the polymer directly in the aqueous medium are reported. In the specific case of the formation of the vesicle via host/guest associations, encapsulation yields as high as 76 % for the MTZ drug have been reported [179].

The reverse emulsion method – similar to the scheme shown on figure 2.35 page 36 – can be used to process the block copolymers. 10 μm vesicles have been obtained with this method [176]. Transposed to microfluidic devices, larger vesicles can be made; 200 μm objects are reported [189]. The encapsulation yield is expected to be high, as most of the aqueous phase containing the molecule of interest will be entrapped in a vesicle. All the solvent-less process reported above are compatible with the processing of proteins. Concerning the encapsulation yield, the results obtained with the liposomes suggests that is should be the most efficient method. This technique is compatible with the process of proteins, and meets the requirements of encapsulation yield.

Table of contents :

Introduction

1. Sensitivity of cells to uneven distributions of peptides and proteins

1.1. Representative proteins of interest

1.2. Characteristic scales: concentrations, time and lengths

1.3. Summary and conclusion

I. Light-controlled release, a review

2. Light-sensitive liposomes

2.1. Light-induced increase of permeability

2.2. Light-triggered pore formation

2.3. Membrane disruption

2.4. Encapsulation yield and preparation conditions

2.5. Summary on light-sensitive vesicles

3. Micro- and nanometer-sized hydrogels

3.1. Photodegradable hydrogels

3.2. Light-triggered gel collapse

3.3. Encapsulation yield and loading constraints

4. Aqueous core—polymer shell capsules

4.1. Layer-by-layer assemblies

4.2. Polymersomes

4.3. Capsules made of solid polymers

4.4. Hybrid membranes

4.5. Role of the stimulation wavelength

Summary

II. Light-sensitive liposomes

5. Surfactant sensitized vesicles

5.1. Liposome solubilization by the azoTAB surfactant

6. Azobenzene-based polymer sensitizer

6.1. Experimental conditions

6.2. Interpretation of typical photo-triggered release patterns

6.3. Data analysis

III. Temperature-sensitive capsules made by the reverse emulsion method

7. PolyNIPAM-based millimeter sized capsules

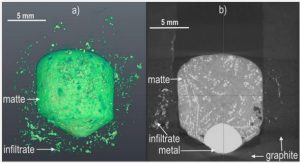

7.1. Adaptation of published protocols

7.2. PolyNIPAM-based capsules

7.3. Effect of mixed membrane composition

8. PolyNIPAM-based nanocapsules

8.1. Description of the synthesis of nanometer sized capsules

8.2. PolyNIPAM nanocapsules characterization

9. UCST polymer-based millimeter-sized capsules

9.1. Characterization of the UCST polymer

9.2. Adaptation of the capsule preparation procedure to the UCST polymers .

9.3. Characterization of capsules made from UCST polymers and ovalbumin

Conclusions & perspectives

Liposomes

Polymer capsules

IV. Appendices

A. Role of molecular gradients on biological systems

B. Currently used gradient generators

C. Materials & Methods

D. Experimental techniques

E. Preparation and characterization of liposomes

F. Preparation and characterization of polymer capsules

G. Quantitative and real-time FRAP measurements

Bibliography