Get Complete Project Material File(s) Now! »

Chapter 2 Stone Fruit Safety: Means and prevention of contamination and detection of foodborne pathogens

Abstract

Contamination of food with human pathogens has been investigated extensively within the past century. Contamination of food, and more recently of fresh produce, with foodborne pathogens is of concern due to an increase in immunocompromised individuals, global procurement patterns and movement of food. Global distribution of food products requires longer food chains, increasing the risk of contamination due to increased handling and inadequate hygiene. A lack of knowledge of the risks associated with poor personal hygiene and inadequate facility sanitation, can lead to an increased risk of contaminating the product while being moved through the chain. Water availability, quality and management are a global concern as in South Africa. Water quality changes seasonally depend on upstream activities that could affect fruit safety, since water comes into contact with fruit when pesticides are applied, through irrigation water, as well as washing and pre-cooling systems. Consumers are now more aware of the possibility of produce contamination and therefore food safety assurance has become important to ensure consumer confidence.

Introduction

Fruit are an important export product of South Africa with 1882.47 million dollars earned during the 2007 season [Food and Agricultural Organisation (FAO), 2010]. Deciduous stone fruit are cultivated in South Africa mainly in the Eastern and Western Cape on 60 653 ha representing plum orchards and 10 000 ha representing peach orchards during the 2008/2009 season. Due to the large amount of fresh produce exported from South African shores, contamination of the fruit is an important consideration (Bean and Griffin, 1990; Garcia-Villanova Ruiz et al., 1987; Lindqvist et al., 2000; Notermans and Borgdorff, 1997). Fresh produce can become contaminated during the various stages of production, packing, distribution or transportation through the cold chain. Product contamination could potentially lead to further proliferation of the pathogen present if the cold chain, locally or globally, is not managed correctly. The global distribution of food products requires more extensive food chains, increasing the risk of contamination due to increased handling and inadequate hygiene. This risk may be increased further due to a lack of knowledge linked with poor personal hygiene and inadequate facility sanitation (De Roever, 1998). Foodborne infections associated with food and more recently fresh produce (Todd, 1997), cause large threats to public health and have a major economic impact within a country. Public health threats are further increased due to a growing number of immunocompromised individuals, global procurement patterns and movement of fresh produce. The aim of this review is to outline all facets involved in growing stone fruit and highlights potential contamination points of fresh produce. The review also covers previous reports of disease outbreaks associated with fresh produce and the early detection and prevention of contamination and ultimately illness due to consumption of contaminated produce.

Stone Fruit

Deciduous stone fruit bear fleshy indehiscent fruit with a single seed. Peaches are soft juicy fruit with yellow flesh and a red-tinted yellow skin and a deeply sculptured stone containing a single seed. Peaches are native to China, but were named Prunus persica L. Batsch because it was thought to have originated in Persia (now Iran). However, it was later discovered that trees were taken to Persia in 2000 B.C. (Anonymous, 2007a). The historical peach cultivation areas are China, Japan, Turkey and Mediterranean countries. In 2009, 1.7 million hectares of land were under peach orchards worldwide with 18.6 million tonnes of peaches produced in the area. The world’s largest producer of peaches in 2009 was China, with 802 686 ha of land under peach cultivation (FAO, 2010). Plums are smooth-skinned, fleshy fruit containing a stone that encloses a single seed. The Japanese Plum (Prunus salicina) dates back to 479 B.C. and originated in China (Anonymous, 2007b). The European Plum (Prunus domesticus) originated near the Caspian Sea and was introduced into Northern America by pilgrims. China was the largest producer of plums in 2009, with 1 663 115 ha of land used for plum production, with 5.4 million tonnes produced (FAO, 2010).

It is not known exactly when stone fruit entered into South Africa but the export of the first consignment of deciduous fruit took place in 1892 by Percy Molteno from the Cape to the United Kingdom (UK) [Hurndall: Deciduous Fruit Producers’ Trust (DFPT), 2005]. Following the beginning of deciduous fruit export, Harry Pickstone imported deciduous fruit trees (50 into South Africa from California, which lead to large areas of Constantia, Stellenbosch and the Hex River Valley being planted by 1894. With increased plantings the export of deciduous fruit increased from 22 000 fruit punnets exported in 1903 to 4.6 million punnets in 1938 increasing further to 7.9 million fruit punnets in 1958. Twenty years later, South Africa was thus exporting to 34 countries on four continents (Hurndall: DFPT, 2005).

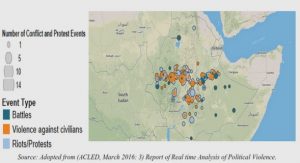

In 2009, South Africa had 6500 ha of land under peach orchards and 10 000 ha plums produced. A number of areas produce stone fruit (Figure 2.1), with the largest being Eastern and Western Cape. In 2008, the Klein Karoo and Berg River produced 23% and 22% respectively of the 4 081 ha of plums cultivated in South Africa (DFPT, 2009). In the Ceres area 39% plums and 17% peaches are produced being the largest peach cultivation area of South Africa with total hectares being 8 490 ha (desert and cling peaches) (DFPT, 2009).

Plums and peaches produced in South Africa go into three possible avenues, export sale being the largest, followed by local sale and then processing. Currently the South African stone fruit industry is export driven with 43 742 tonnes of plums and 8 445 tonnes of peaches exported during 2007 (FAO, 2010). The 2007/2008 statistics showed that plums were mainly exported to Europe (55.8%) and peaches mainly to the Middle East and the Mediterranean (36.97%) (PPECB, 2010). Statistics from 2004 revealed that 12 239 tonnes of plums and 35 576 tonnes of peaches went into the local market, 47 085 tonnes of plums and 7 740 tonnes of peaches went into the export market and 2 545 tonnes of plums and 178 800 tonnes of peaches were processed into canned fruit, jams, dried fruit and juices [Centre of International Agricultural Marketing and Development (CIAMD), 2004 as cited by Hurndall: DFPT, 2005].

The most economically important dessert peach cultivars in the 2007/2008 season were Transvalia with 373 373 cartons passed for export (DFPT, 2009). Transvalia is an early seasonal cultivar, harvested in mid-November (Hurndall: DFPT, 2005). The next most economically important peach, San Pedro, had 126 396 cartons passed for export in 2007/2008 season (DFPT, 2009). San Pedro is harvested in early November. In 2009/2010 season 120 665 metric tons of canning peaches were processed, mainly used for canning (82%) or puree (Canning Fruit Producers’ Association, 2010) The largest production of canning peaches in South Africa in the 2007/2008 season was a yellow cling stone peach Keisie (1 419 hectares and 55 704 cartons released for export) (Hurndall: DFPT, 2005; DFPT, 2009). Kakamas, also a yellow skinned cling stone peach harvested in mid-February produced under 1 273 hectares of land with an export of 21 563 cartons is the second most important canning peach (Hurndall: DFPT, 2005; DFPT, 2009). The plum cultivar that was exported most during the 2007/2008 was Laetitia with 2.2 million cartons passed for export. Laetitia is produced only from 648 hectares of orchard land and is harvested in late January (Hurndall: DFPT, 2005; DFPT, 2009). The second most exported plum is a yellow variety called Songold. Songold’s 1.64 million cartons were produced from 613 hectares of orchard land in 2007/2008 season. Songold is harvested in early February.

Trees are generally planted during the late winter or in early spring as a single block or a mixed cultivar block (two cultivars alternating in two rows (Hurndall: DFPT, 2005) with roots remaining moist prior to planting. Trees are planted manually, except for some larger farms which use mechanical planting machines. Stone fruit are planted at a density of an average 1 250 trees per hectare but often the numbers are doubled. Three years after planting the first plums can be harvested and following two years for peaches, with the full production being reached after five years. Plum and peach trees can bear fruit and be commercially profitable for up to approximately 15 years.

Fruit must be harvested at the correct maturity and under the optimal conditions (SA Fruit Farms, 2010). Harvesting is conducted by hand using the best methodology/ harvesting aids and equipment. Fruit harvesting and packing requires extensive exposure to handling introducing a possible food safety risk if not done within an effective personal hygiene framework and regular training programme. Fruit should be harvested early in the morning when the temperature is 25oC. When in the field fruit need to be kept in cool shaded areas and the field heat needs to be removed within three hours of harvest (Figure 2.2). The temperature of the fruit within the field could allow any potentially present organisms to survive and proliferate.

After harvest, fruit are transported within a half an hour to packhouse where the field heat is removed in a pre-cooling facility at a recommended 12oC (Figure 2.2, 2.3 and 2.4) for three hours (SA Fruit Farms, 2010). Fruit are then moved into the packhouse where they are pre-sorted into fruit for the local or export market (Figure 2.2). Fruit are then sorted and graded according to set size specifications. During sorting, grading and packaging fruit come into direct contact with surfaces and hands, therefore potentially posing a food safety risk due to potential hazards on hands or contact surfaces in the facility (Figure 2.2). Fruit are then moved to the cold store (±0.5oC) for storage until transportation to the specific market, the time of storage is dependent on the market and demand for fruit (Figure 2.2). Plums and peaches are exported according to recommendations provided by PPECB in order to guarantee the quality of the fruit. Peaches are exported at the recommended holding temperature for stone fruit, i.e. -0.5oC for the full voyage from the exporting country to the importing country (Figure 2.2 and Figure 2.3), whereas plums are exported at -0.5oC for 2 days with a subsequent ripening period where the temperature is increased to 7.5oC for 5-10 days, after which the temperature is again lowered to -0.5oC (Figure 2.2 and 2.4). Breaks in the cold chain management pose a food safety risk to fruit. The recommended temperatures are sometimes not adhered to due to logistical problems or ignorance and could potentially lead to a safety or quality breakdown, as indicated in Figure 2.3 and Figure 2.4 as red peaks. A number of observations have been made over the past few years which are a food safety concern. When fruit are transported to the harbour, it has been observed that transport is not done in an adequately cooled truck and therefore fruit temperature increases. In addition breaks in shipment temperatures and during retail sale have been observed. The temperature of the fruit has been observed to increase prior to and after shipment due to delays in filling/emptying of containers or because the container was not adequately cooled. It has also been observed that during distribution to retailers the recommended temperatures are not adhered to due to logistical problems. Following purchasing the produce, consumers often do not refrigerate the product and therefore the fruit are not stored at the correct temperatures.

Threats to the South African Fruit Export Industry

South Africa has a long and proud history of exporting quality produce to mainly European markets. Through research and technology transfer, the South African stone fruit industry has been able to maintain their competitive edge and increase the market share. With globalisation, new threats and opportunities that require a different focus for South African fruit growers and exporters have emerged. The South African government established a Food Safety and Quality Assurance Directorate that falls under the National Department of Agriculture, Forestry and Fisheries. The Directorate controls the Standards Regarding Food Safety and Food Hygiene of Regulated Agricultural Food Products of Plant Origin destined for Export [as stipulated under 4(3)(a)(ii) of the Agricultural Products Standards Act 119 of 1990, and promulgated in notice R707 of 13 May 2005]. International concern over the indiscriminate use of pesticides and the increased occurrence of foodborne illnesses, as well as a range of new emerging diseases, has resulted in retailers and market forces demanding safe produce within a framework of the accountable systems approach. Global GAP and other voluntary standards have been established to ensure that produce being exported is of good quality and safety standards. Countries that cannot adhere to these basic food safety requirements will be excluded from the international arena and denied market access in the global village. For the South African economy to continue its growth and remain internationally competitive the country will have to adapt to these new requirements and implement international standards in food safety. In addition, national requirements and legislation will have to ensure protection for the consumer in both local and export products.

Countries can still set their own safety standards, but they must be based upon sound scientific evidence. The use of accepted international standards are encouraged and provide a much greater potential and safety assurance framework for fresh produce, particularly in developing countries. For safety, the main purpose is to ensure that products are not adulterated nor carry dangerous contaminants such as undesirable microorganisms, pesticides or potential toxic components. The measurement and evaluation of safety standards can be complicated. Of particular concern to first world countries are the potential increase in risks associated with poorly controlled products and subsequent food safety risks of contaminated fresh produce. This is of importance when considering the spread of infectious diseases, foodborne pathogens and the newly emerging and resistant groups of pathogens.

Declaration

Acknowledgements

Summary

Table of Contents

List of Abbreviations

List of Figures

List of Tables

Chapter 1 General Introduction

References

Chapter 2: Stone Fruit Safety: Means and prevention of contamination and detection of foodborne pathogens

Abstract

1. Introduction

2. Stone Fruit

3. Threats to the South African Fruit Export Industry

4. Foodborne Pathogen Contamination within the Fresh Produce Cold Chain

5. Food Safety on Fresh Produce

6. Conclusion

7. References

Chapter 3: Multiplex Polymerase Chain Reaction for the detection of Escherichia coli O157:H7 Listeria monocytogenes, Salmonella enterica subsp. enterica Typhimurium and Staphylococcu aureus, on artificially inoculated fresh produce Stacey Duvenage, Rene Jacobs, Carinne Joubert and Lise Korsten

Abstract

1. Introduction

2. Materials and Methods

3. Results

4. Discussion

5. References

Chapter 4: Assessment of possible foodborne pathogen presence on peaches and in the production and postharvest environments Stacey Duvenage and Lise Korsten

Abstract

1. Introduction

2. Materials and Methods

3. Results

4. Discussion

5. References

Chapter 5: Assessment of possible foodborne pathogen presence on plums and in the production and postharvest environments Stacey Duvenage and Lise Korsten

Abstract

1. Introduction

2. Materials and Methods

3. Results

4. Discussion

5. References

Chapter 6: Growth dynamics of Escherichia coli O157:H7, Listeria monocytogenes, Salmonella enterica subsp. enterica serovar Typhimurium and Staphylococcus aureus under different nutrient and temperature conditions

Abstract

1. Introduction

2. Materials and Methods

3. Results

4. Discussion

Chapter 7: Attachment and colonisation of Escherichia coli O157:H7, Listeria monocytogenes, Salmonella enterica subsp. enterica serovar Typhimurium and Staphylococcus aureus to stone fruit surfaces and survival through a simulated commercial export chain

Abstract

1. Introduction

2. Materials and Methods

3. Results

5. References

Chapter 8: Microbial risk profiles of the South African peach and plum export industry

Abstract

1. Introduction

2. Materials and Methods

3. Results

4. Discussion

5. References

Chapter 9: The Evaluation of a Diagnostic Tool to Assess the Horticultural Safety Management System of Primary Production of Two Peach and Plum Farms in South Africa

Abstract

1. Introduction

2. Methodology

3. Results

4. Discussion

5. References

Chapter 10: General Discussion

References

GET THE COMPLETE PROJECT