Get Complete Project Material File(s) Now! »

Whole Construct Strain Analysis of Confined Hydrogels

Abstract

Hydrogels are common scaffolds used to maintain chondrocyte phenotype in culture for mechanobiology and tissue engineering studies. However, the internal strain field and the zone-specific strain patterns of chondrocytes within hydrogels under dynamic compressive strain have not been well characterized. In this study, we describe a methodology to characterize the compressive strain fields within the surface, middle and bottom zones of both confined collagen and agarose hydrogel constructs, in response to dynamically applied compressive strain. Hydrogel microstructure and chondrocyte deformation were also analysed and compared to uncompressed conditions using scanning electron microscopy. We observed inhomogeneous strain distributions within and between the three zones of both collagen and agarose hydrogel constructs. In collagen gels, we observed that the microstructure varied greatly between uncompressed gels to gels with 5% applied compression. The percentage porosity in the surface zone of the gel decreased significantly upon initial application of 5% compression, but remained unchanged when compressed further to 15%. In agarose gels, only the cells in the middle zone of the gel deformed significantly under compression while cells in the other zones underwent deformation that was not statistically significant. These findings indicate that deformation of chondrocytes seeded hydrogels under compression is both inhomogeneous and spatially-dependent. Therefore, it is important to consider these inhomogeneities in order to accurately understand how mechanical stimuli may affect chondrocyte behaviour.

Introduction

Dynamic loading plays a significant role in modulating the metabolism of chondrocytes. This is evident in the many experimental studies that apply static and dynamic loading on cell-seeded hydrogels [1–8]. There are various mechanical stimulating devices that apply dynamic compression to chondrocyte-hydrogel systems. However, there are several difficulties with these systems, one of which is the inherently weak nature of hydrogels. Therefore, to overcome this, the use of support platforms are used [9,10].

The current cell stimulating device, the cell-gym IV, uses silicone baths [11] that can be used to support hydrogels during mechanical stimulation. Therefore, the strain distribution through the hydrogel first needs to be identified to determine the correlation between the applied mechanical strain to the system and the strain cells seeded within experience, to accurately understand the mechanical effects. This is because hydrogels are anisotropic materials, which have been suggested to distribute dynamic strain inhomogeneously through them. This implies that the local microscopic strains will not be the same as the applied global macroscopic strain under dynamic compressive loads [12]. This complex response to load is often neglected [13,14], and the strain distribution through dynamically loaded cell-seeded hydrogels have not been validated.

Frequently, analysis of chondrocyte behaviour to dynamic mechanical load focuses on one zone of hydrogel samples [6,8] or the effects of the load on chondrocytes are often investigated after homogenizing the whole sample [15]. Most cell mechanobiological studies assume that the amount of applied load is transferred equally and homogeneously to the hydrogels during dynamic loading, and subsequently onto the cells. However, knee cartilages have a complicated inhomogeneous structure [16] and chondrocytes that reside in it are very sensitive to the mechanical cues from their surrounding environment [17,18], therefore it is important to quantitatively characterize the effect of this loading throughout a 3D construct during dynamic loading. It has also become apparent that to understand biological systems comprehensively, there is a need to examine cells or samples in their entirety.

Therefore, the hypothesis for this study is that under dynamic loading, the strain distribution within hydrogels is not homogenous, and that the continuously applied strain is not evenly transferred into the hydrogels and the cells. Therefore, the aim of this study was to develop a new experimental system to analyse the compressive strain fields in three separate zones (surface, middle and bottom) in 3D hydrogel scaffolds and to investigate the effect of dynamic loading on the microstructure and cellular deformation on the chondrocytes seeded within two mechanically and microstructurally different hydrogels; collagen and agarose [19–22].

Methods

Chondrocyte Cell Culture and Preparation of Constructs

An immortalised mouse articular chondrocyte cell line (H5 line, kindly gifted by Dr Martin Knight, Queen Mary University of London) was used in this study [23]. Chondrocytes were seeded in culture flasks containing Dulbecco’s Modified Eagle Medium (DMEM) supplemented with 10% foetal bovine serum (FBS) and 0.1% penicillin/ streptomycin (Life Technologies NZ Ltd) at 37°C/5% CO2. At approximately 80% confluence, chondrocytes were trypsined, and viable cells determined with trypan blue solution (Sigma-Aldrich, MO, USA), were counted, and seeded into gels.

Cell-Free and Cell-Seeded Collagen Constructs

Cell free collagen constructs were prepared by first neutralising rat tail type I collagen (BD Biosciences) with 1M NaOH (0.023× collagen volume), then diluting to a final concentration of 4 mg/ ml in DMEM and 10% FBS. Cell-seeded collagen constructs were prepared with the final concentration of 4 mg/ ml diluted using a cell-suspension density of 4 x 105 cells/ ml.

Cell-Free and Cell-Seeded Agarose constructs

Cell-free agarose was prepared by autoclaving 4% (w/v) agarose powder (type VII; Sigma-Aldrich, Saint Louis, MO) with distilled phosphate buffered saline (PBS). Cell-seeded agarose constructs were prepared by adding a cell suspension of 8×105 cells/ ml in culture medium to equal volume of 8% (w/v) agarose to give a final concentration of 4×105 cells/ ml.

Both liquid collagen and molten agarose were pipetted into specially designed moulds made from silicone [24] to form a rectangular gel construct measuring 28×18×3 mm. Prior to gel casting, silicone baths were sterilized in 70% ethanol for 30 minutes and allowed to dry. They were assembled in sterile conditions and pre-stretched in holders prior to use to prevent buckling and reduce interference with the deformation of the gel constructs. In order to analyse the degree of deformation in each zone of the gel, carbon powder (Electroflash Resourcing Ltd, NZ) was distributed within either the surface, middle or bottom zones of the gel during casting. The zones and process are described schematically in Figure 3.1. Collagen gels were set at room temperature for 20 minutes while agarose gels were set at 4°C for 20 minutes. Both cell-free and cell- seeded constructs were subsequently maintained within the silicone baths in DMEM + 10% FBS at 37˚C/5% CO2 for 7 days. Culture media were replaced every 2 days. At the end of 7 days, compression was applied to cell-hydrogel constructs.

3D Gel Compression Device

The device used to apply compression to the hydrogel samples was an existing device [11] that was designed to apply precise magnitudes of uniaxial strain via silicone baths. The device was secured on a lighting stage directly under a camera (Sony NEX-5 with macro fitted Voigtänder 40mm f/1.4X NOKTON Classic lens) which allowed the whole depth of the construct to be in focus. The silicone baths were attached to the device via screws and maintained pre-stretched; compression was applied in the X direction (Figure 3.2), in a continuous fashion that simulates the compression phase of dynamic loading at a rate of 20 µm/ s. Images of the gel were continuously acquired at every 0.7% compressive strain during the loading period.

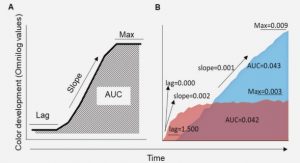

Whole Hydrogel Construct Strain Analysis

Three samples were measured and analysed for each zone. Images (3344×2224 pixels) were analysed using a MATLAB program developed and validated by Malcom et al [19,20]. Briefly, the program applied a grid map to the reference image (uncompressed). Each pixel was then traced in the sequential images through the compression of the gel using a cross-correlation technique. The carbon powder created a unique arrangement that allowed its movement to be tracked and coordinates saved. Each image was compared to the reference image, and the engineering strain between each data point was calculated, which was repeated for all data points in the image to measure the strain distribution in the gel during compression. The strains are the strains measured in the X direction. The strain values were plotted to their associated coordinate against the length of the construct, relative to the fixed end of the construct, using CMISS, open source software for computational biomechanics developed by the Auckland Bioengineering Institute (www.cmiss.org).

The immobile end of the construct clamped to the decice is here in termed “fixed end”; the other end of the construct where compression is applied by the device is here in termed “mobile end” (Figure 3.2).

SEM Sample Preparation

Cell-seeded constructs were either left uncompressed, or subjected to 5%, or 15% compression then washed with PBS, and fixed in using Karnovsky’s fixative for 5 days at 4°C. Karnovsky’s penetrates quickly and provides a high quality fixation for ultra-structural analysis. Samples were washed with PBS and sectioned longitudinally into surface, middle and bottom zones using a flat blade. Constructs were dehydrated in ascending concentrations of aqueous ethanol solutions (50, 60, 75, and 90%) and absolute ethanol at 4°C. Constructs were then critically point dried, and sputter coated with gold. Samples were imaged using a Philips FEI XL30 S-FEG at 5kV and 20,000X magnification.

SEM Image Analysis

All SEM images were analysed using NIH ImageJ software [21] and two parameters were measured; 1) porosity in collagen gels, and 2) mean cell diameter ratio for cells in agarose. The mean grey value of the porous region was obtained by averaging intensity values of five sections within a 20,000× image. The particle analysis tool of ImageJ was used to determine the mean pore size in microns and the fractional area of the pores, and porosity was expressed as a percentage. The aspect ratio (AR), equation (1), previously used in other studies [6–8], were calculated manually using the line-drawing feature in ImageJ, to measure the cell diameters in the X and Y directions. Up to 5 cells were measured in each zone.

The mean fibre diameter of collagen gels were also measured, to ensure the constructs were comparable with those used in other studies. The fibre diameters were measured using a similar method used by Raub et al [25], by using a line-drawing feature of ImageJ. Mean fibre diameters were calculated by sampling twelve 2 × 2 µm sections from each of five 20,000X images of cell-seeded collagen constructs at each region (surface, middle and bottom), and were measured by setting a minimum intensity threshold based on the average of the mean grey value of the SEM image.

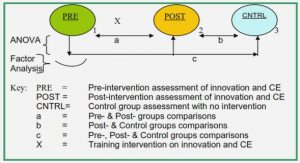

Statistical Analysis

Data were expressed as the mean value ± standard error mean (SE). Two-way ANOVA with a Bonferroni post-hoc test was performed using GraphPad Prism version 6.0 (www.graphpad.com). Statistical significance was determined with a p value < 0.05.

Results

Strain maps showed that when a compressive strain is applied in successive increments to hydrogels, the strain is non-uniformly distributed across the gel. This strain distribution is in agreement with current theories that hydrogels do not respond isometrically with a uniformly distributed strain [12,26,27]. Our study used two microstructurally and mechanically different hydrogels, both of which showed inhomogeneous strain distributions under dynamic compressive strain. In fact, when 15% compression is applied, regional strains reached only up to 11%, indicating that loading type (static or dynamic) plays an important role in strain transfer during compressive loading.

Zonal Strains and Porosity Changes in Collagen Constructs Under Compression

Figure 3.3 A shows the distribution of local strains within chondrocyte-seeded collagen constructs at 5% and 15% applied compression within three different zones of the gel, with distinct differences in local strain patterns demonstrated at each zone.

The greatest magnitude of local strain was experienced at the bottom zone of the collagen gels, compared to the middle and surface zones at both 5% and 15% gross applied compression. At the bottom zone of the gel, the strain appeared to be relatively homogenous across the length of the gel with both 5% and 15% applied compression. In contrast, at both 5% and 15% compression, the middle zone of the gels experienced higher levels of strain at the mobile end, which decreased towards the fixed end of the gel (Figure 3.3 A). The greatest inhomogeneity in strain distribution patterns, however, was observed at the surface where high strain zones appeared near the mobile end. Further analysis showed high strains formed were due to buckling of the cell-hydrogel constructs. The porosity of collagen constructs was significantly lower at the bottom zone of the gel, compared to the middle and surface zones (p < 0.001) (Figure 3.3 B).

Zonal Strains and Cell Deformation in Agarose Constructs Under Compression

Figure 3.4 A shows the local strains of agarose gel following 5 and 15% compression within the three zones. At 5% compression, the local strain patterns within all three zones of the gel were similar to collagen gel at 5% compression. Similarly, the greatest level of local mean strain, and strain homogeneity was observed at the bottom zone of the gel. At the middle zone of the gel, the mobile end experienced higher levels of strain, which became less towards the fixed end of the gel. The surface zone also displayed a similar pattern to collagen gels where high strain zones appeared near the fixed end. In contrast to the collagen gels, agarose with 15% compression showed high strain zones near the fixed end in local strain across all zones of the gel along the length of the construct.

Changes in cell diameter were measured in agarose gels and there was no difference in AR between each zone of the gel within each construct (Figure 3.4 B). However, we observed an overall decrease in AR with an increase in application of strain. This correlation between the decreasing chondrocyte size with compression is in agreement with other studies [6,8,28]. The most significant decrease in AR was observed at middle zone of the gel, from 0-5% applied strain (p < 0.01), and between 5-15% strain (p < 0.001), which may be associated with the middle zone of the gel experiencing the highest level of mean local strain at 15% compression.

Discussion

The aim of this study was to determine the degree of homogeneity of dynamically applied compressive strain within chondrocyte-seeded hydrogels. Carbon powder was used to track the deformation of hydrogel constructs under applied compression up to 15%. The deformation was then analysed to give maps of the distributed local strain within the hydrogel construct under the applied loads. The mechanical effect on the ultrastructure properties of cell-seeded collagen and agarose hydrogels were also examined.

The strain mapping technique used for whole construct strain analysis has been successful in identifying the deformation patterns of soft materials with randomly dispersed particles [29–31]. This technique has been applied to measure the strain distribution patterns of the silicone bath which were revealed to be uniformly distributed [11]. Therefore, the influence of the silicone bath’s strain on the strain patterns of the cell-hydrogel constructs is minimized. In addition, the local strain patterns demonstrated at each zone of the gel were consistent between different constructs and between two mechanically different hydrogels.

Our strain-mapping technique enables us to characterize the strain distribution through the 3D depth of the gel during dynamic loading in a non-intrusive manner. A study had reported that the strain distribution within hydrogels were uniform [32]. However, the method used in their study involved cutting constructs in half and observing the deformation of the hydrogel on the cut plane. Invasive methods like these changes the boundary conditions of the hydrogels, therefore the natural deformation patterns of the constructs cannot be observed. The ability to observe and analyse whole construct strain distribution is important, as it allows us to determine the magnitude of strain throughout the construct. Studies with similar mechanical setup, applying mechanical loads to cell-seeded hydrogels using silicone dishes, have assumed that the uniform strain distribution observed in silicone baths is also achieved in the hydrogel [9,10,14]. However, our findings show that the strain distribution in confined hydrogels during dynamic loading is non-uniform.

Studies have often determined the homogeneity of construct or cellular strain using static compression [6,7,28,33,34]. The homogeneity of strain under static load is reported as homogeneous, however this is due to the inherent stress-relaxation properties of hydrogels [35,36]. In contrast, our results reveal that during dynamic compression, the strain distribution through a construct is not homogenous. The strain maps showed that when a compressive load is applied in a dynamic mode to hydrogels, the strain is non-uniformly distributed across and throughout the hydrogel construct. A potential explanation is that natural inhomogeneities that within hydrogels affected the hydrogels’ microstructure, consequently affected the distribution of strain throughout it. Hydrogels are formed by gelation kinetics, and during gelation, microstructural differences can occur, a natural property of hydrogels. Differences such as crosslinking formation among the same polymer chain instead of with other chains, chain entanglements that tend to slip under external strain, detangling chain ends or chains forming closed loop within themselves [26]. These inherent occurrences within hydrogel formation have been postulated to affect polymer network connectivity, consequently influencing gel morphology leading to non-uniformity [27]. Another study had also postulated that natural inhomogeneities within agarose changes the strain distribution patterns when the hydrogel is compressed [37]; the study had found that the strain field patterns in their experiment were more inhomogeneous when compared to their computational simulation of their experiment, where the material properties of agarose were assumed perfectly homogeneous in the computational model. These assumptions correspond to current theories that hydrogels do not respond isometrically with a uniformly distributed strain [12,26,27]. Our study used two microstructurally and mechanically different hydrogels, both of which showed inhomogeneous strain distributions under compressive strain.

An example of a microstructural difference that may have caused inhomogeneous strain distribution is shown in the SEM images of collagen gel, where there the bottom zone is significantly less porous (p<0.001) and inversely, the mean fibril diameter was significantly larger (p<0.001). Figure 3.5 show the fibril diameter in the surface and bottom zone of the cell-seeded collagen gel constructs. The left image shows collagen fibrils imaged in the surface zone, where the fibrillar diameter is comparable to values measured by others in literature in unconfined collagen cultures [25,38–40]; while the image on the right is collagen fibrils imaged from the bottom zone. Stiffness of the hydrogels increases as porosity decreases, which also influences the fluid flux within the gel, changing its deformational characteristic [41–43]. Therefore, the low porosity in the bottom zone is likely to have influenced the high local strain and homogeneity in strain pattern under both 5% and 15% compression. Chondrocyte matrix development during culture period may also contribute to inhomogeneous behaviour. Due to spatial variations in nutrition, matrix content may generally be higher in the outer zones of the construct than in the middle zone [44,45].

Contents

Abstract

Acknowledgements

List of Tables

List of Figures

Abbreviations

Co-Authorship Forms

1 Research Overview

1.1 Thesis Organisation

1.2 References

2 Literature Review and Aims

2.1 Articular Cartilage

2.2 Cartilage Composition and Structure

2.3 Cartilage Injury and Development into Osteoarthritis

2.4 Current Research

2.5 Research Aim

2.6 References

3 Whole Construct Strain Analysis of Confined Hydrogels

3.1 Introduction

3.2 Methods

3.3 Results

3.4 Discussion

3.5 Conclusions

3.6 References

4 Device Design and Development

4.1 Device

4.3 Discussion

4.4 Summary

4.5 References

5 Construct Strain Distribution and Cellular Deformation

5.1 Introduction

5.2 Methods

5.3 Results

5.4 Discussion

5.5 Conclusion

5.6 References

6 The Effect of Uniaxial and Combination Strain Loading on Chondrocytes

6.1 Introduction

6.2 Methods

6.3 Results

6.4 Discussion

6.5 Conclusion

6.6 References

7 Conclusions and Future Directions

7.1 Chapter Conclusions

7.2 Future Directions

7.3 Final Remarks

7.4 References

GET THE COMPLETE PROJECT

Finding the Links between Knee Injuries and Osteoarthritis