Get Complete Project Material File(s) Now! »

In situ implant formation and drug release measurements

One hundred microliters of the respective formulation was injected at the bottom of an Eppendorf vial using a standard syringe. One and a half milliliters preheated (37 °C) phosphate buffer pH 7.4 (USP 35) was carefully added using a pipette, initiating solvent exchange and implant formation. The vials were horizontally shaken at 37 °C at 80 rpm (GFL 3033; Gesellschaft fuer Labortechnik, Burgwedel, Germany). At pre-determined time points, the bulk fluid was completely withdrawn and replaced with fresh phosphate buffer pH 7.4. The drug content in the samples was determined UV-spectrophotometrically (λ = 325 nm; UV-1650PC, Shimadzu, Champs-sur-Marne, France). For reasons of comparison, the commercially available formulation Parocline® was also studied (note that this product contains a different drug: minocycline). In this case, the 100 µL of formulation was injected using the supplied syringe and 0.01 % sodium metabisulfite was added to the release medium to improve the drug’s stability. The drug content was determined UV-spectrophotometrically at λ = 324 nm (UV-1650PC). Each experiment was conducted in triplicate, and the results are presented as mean values ± standard deviation.

Monitoring of dynamic changes in the implants’ mass

Implants were prepared and treated as described in Section 2.3. In situ implant formation and drug release measurements. At pre-determined time points, implants were weighed (after removal of excess water by careful blotting with precision wipes) [mass (t)]. The mass change in percent was calculated as follows:

mass change (%) = 100 * [mass (t) – mass (t=0)] / mass (t=0)

where mass (t=0) is the initial weight of the formulation used for implant preparation.

Mechanical and adhesive properties

The mechanical and adhesive properties of the investigated in situ forming implants were determined with a texture analyzer (TA.XT.Plus; Stable Micro Systems, Surrey, UK) using the experimental set-up schematically illustrated in Figure 1.

Agarose was dissolved in boiling water (0.6 % w/v), and the solutions were cast into Petri dishes (diameter = 9 cm). Upon cooling to room temperature, gels formed. At the center of the gels, cylindrical holes (diameter = 6 mm) were made and filled with 100 « L liquid formulation using a standard syringe and a drop of distilled water. Upon solvent exchange, the implants formed. At pre-determined time points, a spherical probe (diameter 5 mm) was driven downwards (at a speed of 0.5 mm/s). Once in contact with the implant, the applied force and displacement of the probe were recorded as a function of time. When the penetration depth was 1.5 mm, this position was held for 60 s. Then, the probe was driven upwards at a speed of 10 mm/s.

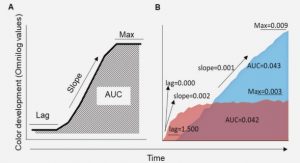

Figure 2 shows a typical force-time diagram obtained with this type of measurements. Here, the maximum deformation force (Fmax deformation) is the force measured at maximum probe penetration into the implant. The force measured after the 60 s holding time is called “remaining force” (Fremaining). In this study, the “adhesion force” is defined as the maximum force measured with this set-up during the upward movement of the probe, accounting for the negative sign/direction of the force (Fadhesion). The ratio “Fremaining/Fmax deformation” is used as a measure for the elasticity/plasticity of the implant. High values indicate high elasticity, low values indicate high plasticity. Each experiment was conducted in triplicate, and the results are presented as mean values ± standard deviation.

Antibacterial activity

The in vitro efficacy of the investigated implants against bacteria associated with periodontitis was assessed using the agar well diffusion method. Columbia agar was prepared from Columbia base, glucose, cysteine hydrochloride, and agar. The systems were sterilized in an autoclave (121 oC for 15 min). Prior to plating, Columbia agar was enriched with defibrinated horse blood (5 % v/v) and cast into Petri dishes. After cooling to room temperature, 0.1 mL of the following bacterial suspensions were inoculated onto the agar surface: Streptococcus sp. (1) (D36A12), Streptococcus sp. (2) (D20B9), Streptococcus salivarius (D28A9), Streptococcus sanguinis (D28A11), and Streptococcus cristatus (D18A2) (which were isolated from samples from periodontal pockets from patients suffering from periodontitis). A cylindrical hole (diameter = 6 mm) was subsequently made at the center of the agar, and filled with 30 µL of liquid formulation using a standard syringe. Upon solvent exchange, the implants formed in situ. The Petri dishes were incubated for 4 d under optimum culture conditions (35 °C, anaerobic atmosphere) (Whitley A85 workstation, Don Whitley Scientific, West Yorkshire, UK). The diameter of the observed bacteria growth inhibition zones around the center of the Petri dishes was measured using a ruler. Each experiment was conducted in triplicate, and the results are presented as mean values ± standard deviation.

Results and discussion

Effects of the addition of plasticizers

Figure 3a shows the impact of adding 10 % or 20 % ATBC or DBS on the adhesion forces of in situ forming implants, based on PLGA RG 502 H (37 % w/w) and loaded with 10 % doxycycline hyclate. The adhesion force was measured as a function of the exposure time to phosphate buffer pH 7.4. For reasons of comparison, also plasticizer-free implants (dotted curve) as well as the commercially available product Parocline® were studied. Very clearly, the addition of the plasticizers significantly increased the adhesion forces of the systems (probably due to the increased mobility of the macromolecules, allowing for facilitated interaction with the environment). This can be expected to be a great benefit in practice, since accidental expulsion of the implants (or parts thereof) from the periodontal pockets of the patient is a major source of uncertainty for all currently available formulations. This can at least partially be attributed to the non-negligible flow of gingival crevicular fluid [48]. Consequently, it is uncertain how much drug is delivered for which period of time at the site of action. The plasticizer-containing systems show a promising potential to overcome this crucial practical hurdle: As it can be seen in Figure 3a, all ATBC/DBS containing implants showed much higher adhesive forces than the commercially available product Parocline® during the entire observation period. The observed time-dependent changes can at least partially be explained by the dynamic changes in the systems’ composition (e.g., decreasing NMP content, increasing water content), which are particularly pronounced at early time points. Furthermore, it can be seen in Figure 3a that increasing the plasticizer level generally leads to increased adhesion forces, irrespective of the type of plasticizer.

In addition to the adhesion/stickiness of the in situ formed implants, also their elasticity/plasticity can be expected to play a major role for their residence times in the patients’ periodontal pockets: If the system is difficult to deform plastically, the implant is unlikely to be able to adapt its geometry to dynamic changes in the periodontal pocket’ size and shape with time. A fully elastic implant would force the periodontal pocket to keep its geometry and dimensions, which is not desirable. As a measure for the “plasticity” of the investigated in situ forming implants, the ratio of the “force remaining at the end of the 60 s holding time” (Fremaining) to the “maximum deformation force” (Fmax deformation) was used in this study (Figures 1 and 2). A value of “1” indicates that the system is ideally elastic (does not change its inner structure during the holding time in a permanent manner and fully recovers, once the pressure is released), whereas a low value indicates that the implant structure at least partially changes in a permanent manner during the holding time. As it can be seen in Figure 3b, all the investigated in situ forming implants exhibit much lower Fremaining/Fmax deformation ratios than Parocline®, indicating that they are much more easy to deform in a permanent manner and can more likely adapt to changes in the patients’ pockets’ geometry.

Antimicrobial activity

Figure 4a shows the inhibition zones observed with in situ forming implants based on PLGA RG 502 H (37 % w/w), loaded with 10 % doxycycline hyclate and containing 10 or 20 % ATBC or DBS (as indicated). For reasons of comparison, also “plasticizer-free” and “plasticizer-free and drug-free” systems have been studied. The investigated bacteria (isolated from periodontal pockets from patients suffering from periodontitis) were 5

Streptococcus strains, two strains could not be identified to the species level, the others were Streptococcus salivarius, Streptococcus sanguinis and Streptococcus cristatus. Very clearly, all drug-loaded implants were effectively limiting the growth of all these bacteria. The measured inhibition zone diameter varied from 2.4 to 3.5 cm, depending on the specific bacterial strain. Importantly, the addition of 10 % or 20 % ATBC or DBS did not alter the antimicrobial activity of the systems. As an example, Figure 4b shows a picture of a Petri dish incubated with Streptococcus sanguinis for 4 d. The white circle in the middle shows an in situ formed implant based on PLGA RG 502 H (37 % w/w), loaded with 10 % doxycycline hyclate and containing 10 % ATBC. Figure 4c is a zoom on the center of this Petri dish, highlighting the inhibition zone and the implant. The negative controls (implants free of drug) did not show any inhibition of the proliferation of the bacteria (Figure 4a).

Based on these results, 10 % ATBC was selected for further experiments, showing a substantial increase in the adhesive force, while providing good deformability as well as a clear antimicrobial activity, and requiring only the addition of a limited amount of substance. To further improve the implants’ properties (especially, adhesion to the periodontal pocket and plasticity), a second type of polymer was added to the systems.

Table of contents :

INTRODUCTION

1Periodontal)diseases

1.1.!!Definition!

1.2.!!Treatment!

1.2.1.!!Non2surgical!treatment!

1.2.1.1.!!Antimicrobial!choice!

1.2.1.2.!!Clinical!studies!on!adjunctive!antimicrobial!therapy!

1.2.2.!!Surgical!treatment!

2.Local)controlled)delivery)systems)for)the)treatment)of)periodontitis)

3.1.!!Compositions!of!in!situ!forming!implants!based!on!solvent!exchange!

3.1.1.!!Solvent!

3.1.2.!!Polymer!

3.1.3.!!Drug!

3.2.!!Mechanism!of!drug!release!from!PLGA2based!in!situ!forming!implants.!

3.2.1.!!Release!mechanism!

3.2.1.1.!!Diffusion!

3.2.1.2.!!Erosion!

3.2.2.!!Burst!release!and!phase!inversion!dynamic!

3.3.!!Impacts!of!various!parameters!on!the!drug!release!of!PLGA2based!in!situ!forming! implants!

3.3.1.!!Solvent!

3.3.2.!!Polymer!

3.3.2.1.!!Molecular!weight!

3.3.2.2.!!Polymer!concentration!

3.3.2.3.!!Functional2end!group!

3.3.2.4.!!Ratio!of!lactic/glycolic!acid!(L:G)!

3.3.3.!!Drug!

3.3.3.1.!!Drug!properties!

3.3.3.2.!!Drug!concentration!

3.3.4.!!Additives!

3.3.5.!!Injection!site!

3.3.5.1.!!Bath!composition!

3.3.5.2.!!In!vitro!–!in!vivo!correlation!

4.))Research)objectives)

References!

Abstract)

1.)Introduction)

2.)Materials)and)methods)

2.1.!Materials!

2.2.!Preparation!of!the!liquid!formulations!

2.3.!In!situ!implant!formation!and!drug!release!measurements!

2.4.!Monitoring!of!dynamic!changes!in!the!implants’!mass!

2.5.!Mechanical!and!adhesive!properties!

2.6.!Antibacterial!activity!

3.)Results)and)discussion)

3.1.!Effects!of!the!addition!of!plasticizers!

3.2.!Antimicrobial!activity!

3.3.!Effects!of!the!addition!of!a!second!type!of!polymer!

3.4.!Drug!release!kinetics!

4.)Conclusion)

References!

Abstract)

1.)Introduction)

2.)Materials)and)methods)

2.1.!Materials!

2.2.!Preparation!of!the!liquid!formulations!

2.3.!In!situ!implant!formation!and!drug!release!measurements!

2.4.!Monitoring!of!dynamic!changes!in!the!implants’!mass!

2.5.!Electron!paramagnetic!resonance!(EPR)!measurements!

2.6.!1H!NMR!measurements!

2.7.!Optical!microscopy!

2.8.!PLGA!degradation!

2.9.!Microbiological!tests!

3.)Results)and)discussion)

3.1.!Impact!of!HPMC!addition!on!the!implants’!key!properties!

3.2.!Monitoring!of!the!in+situ!implant!formation!by!EPR!and!1H!NMR!

3.3.!Optical!microscopy!

3.4.!Antimicrobial!activity!

4.)Conclusion)

References!

Abstract)

1.)Introduction)

2.)Materials)and)methods)

2.1.!Materials!

2.2.!Preparation!of!the!liquid!formulations!

2.3.!In!situ!implant!formation!and!drug!release!measurements!

2.4.!Monitoring!of!dynamic!changes!in!the!implants’!mass!

2.5.!Electron!paramagnetic!resonance!(EPR)!measurements!

2.6.!Mechanical!and!adhesive!properties!

2.7.!Optical!microscopy!

2.8.!Microbiological!tests!

3.)Results)and)discussion)

3.1.!Key!properties!of!the!implants:!Adhesiveness,!plasticity!and!drug!release!

3.2.!Underlying!mass!transport!mechanisms!

3.3.!Antimicrobial!implant!activity!

4.)Conclusion)

CONCLUSION))

RESUME))